Guangzhou, China – May 29, 2025 – KENGIC, an intelligent logistics and intelligent manufacturing system solution provider with propriety core technologies and products, participated in the LET-a CeMAT ASIA 2025 exhibition in Guangzhou from 21st to 23th May. The event served as a critical platform for KENGIC to showcase its comprehensive portfolio of advanced technologies, empowering various industries including automotive, tire, food cold chain and healthcare globally to embrace the future of intelligent manufacturing.

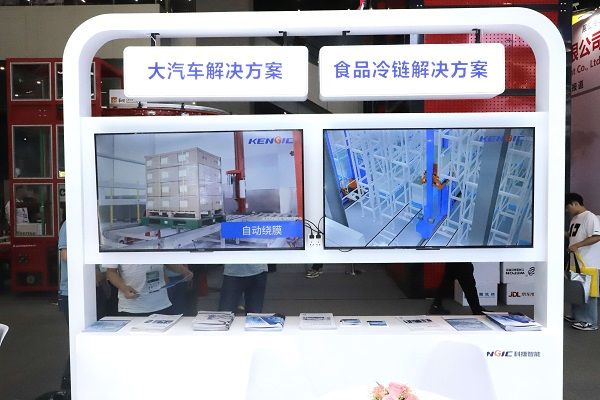

In response to the needs of the automotive industry, KENGIC presented an integrated one-stop solution encompassing intelligent warehousing of components and flexible assembly of complete vehicles. This solution applies to various components, including power systems, lithium battery materials, automotive electronics, drive systems, and tires. Specifically within the tire sector, KENGIC provides comprehensive intelligent logistics and warehousing solutions that cover the entire production process. By integrating self-developed core technologies such as gantry robots, EMS systems, and SRM, along with highly sophisticated intelligent management systems, KENGIC achieves full-process automation and intelligent management, ranging from raw material storage and production logistics distribution to finished product warehousing and shipping.

In the food cold chain industry, KENGIC delivers end-to-end solutions featuring data flow coordination and software-hardware integration through its proprietary core automated 3D cold storage systems and intelligent management systems. For the healthcare industry, KENGIC offers a wide range of customizable products that establish a digitally integrated model and provide AGV-based intelligent high-speed sorting solutions, assisting enterprises in achieving both regulatory compliance and operational efficiency.

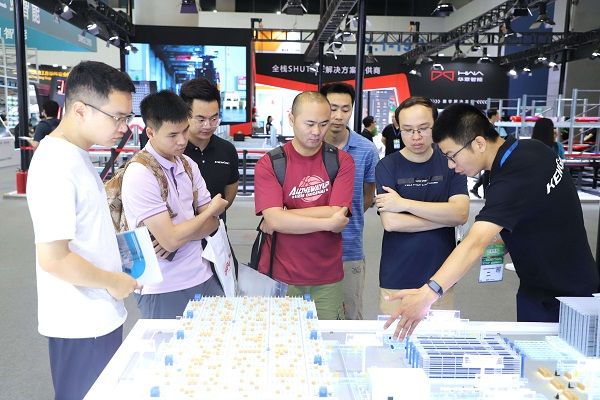

At the exhibition, KENGIC spotlighted its Smart Factory Solution and showcased a sandbox demonstration of this solution, specifically designed to tackle the distinct challenges faced in discrete manufacturing and process industries. This comprehensive solution encompasses the entire business process and features a range of core products, including raw material pallet SRM systems, raw material tote Miniload systems, AGV-based picking areas, semi-finished product assembly lines, semi-finished product CTU warehouses, multi-shuttle storage systems for semi-finished product totes, general finished product assembly lines, specialized finished product assembly lines, automated packaging and palletizing systems, four-way multi-shuttle storage systems for finished product pallets, circular shuttle systems, as well as loading and shipping zones. By addressing a broad spectrum of practical operational challenges and pain points in material storage, transportation, and production processes, this solution offers significant value to customers.

Another highlight at KENGIC’s booth is its second-generation AirRobot, which incorporates advanced lightweight and flexible technologies. By adopting a double-deep storage method, it achieves a 20% increase in space utilization under the same floor area. AirRobot’s movement speed has been increased to 3.5 m/s, with the efficiency of picking and placing goods in totes improved to within 5 seconds. The system utilizes AGVs for seamless connection and efficient transfer of goods, significantly enhancing automation and overall material handling efficiency. Additionally, it is equipped with state-of-the-art sensor fusion technology, achieving a movement positioning accuracy of ±2 mm. Through deep integration with the warehouse management system (WMS), the system can automatically optimize transportation routes, thereby minimizing idle travel and waiting times, and further enhancing operational efficiency.

Apart from showcasing cutting-edge technologies and advanced solutions, KENGIC also provided interactive demos to facilitate hands-on experiences, fostering meaningful dialogues and collaborations. “We are truly impressed by the enthusiasm and active engagement at CeMAT ASIA 2025,” said Head of the South China Region at KENGIC. “This event has reinforced our commitment to delivering innovative, customer-centric solutions.”

A key highlight of the exhibition was KENGIC receiving the “2024–2025 Golden Ant User's Choice Award for Most Popular Logistics Equipment Provider”, a testament to its industry leadership and technological excellence. The company also engaged with leading vertical media outlets in exclusive interviews, sharing its vision for smarter, more connected manufacturing ecosystems.

“We extend our gratitude to all attendees, partners, and the CeMAT ASIA team for making this exhibition a resounding success,” the spokesperson added. “Stay tuned for more updates as we continue to drive innovation in global manufacturing.”

We will reply you within 24 hours