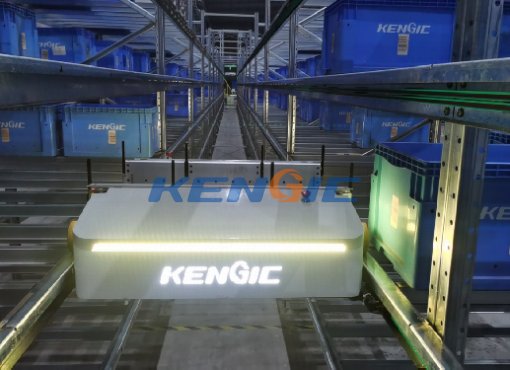

Single-deep & Multi-deep

Modular Design

High System Efficient

Green Technology

Variable Distance Function

As the core equipment of the multi-shuttle system, the main function of tote tow-way shuttle is to transport tote from one location to another. Depending on the model, the shuttle can perform straight-line fixed distance, straight-line variable distance, and 90° two-way walking to pick up and place goods. Its product structure mainly consists of traveling gear train, fork components, control components, etc.

Walking Speed 5m/s

Walking Acceleration 2m/s²

Positioning Accuracy ±3mm

Shuttle Size (length x width x height)

1190×790×330 (single-deep) 1190×950×330 (double-deep)

Rated Load 35kg

Max. Load 50kg

We will reply you within 24 hours

No. 132-1, 201, Gao Yi Road, Gaoyang City, Gyeonggi Province, Republic of Korea

QD HQ (North China): No. 21, Jinye Rd, High-tech Zone, Qingdao City, Shandong Province, China

SH Branch (East China): Building 23, Libo Business Center, Lane 379, Hongmei South Road, Minhang District, Shanghai City, China

CD Office (Southwest China): Room 2103, Taizhoushangren Building, Zhaojue Temple, No. 80 Heng Road, Chenghua District, Chengdu City, China

GZ Office (South China): Room 2112, Yanqiao Building, No. 89 Yanling Road, Tianhe District, Guangzhou City, Guangdong Province, China

SZ Office (South China): Room B1, 13th Floor, Building 12, Lehui Science and Technology Innovation Center, No. 489 Jihua Road, Bantian Sub-district, Longgang District, Shenzhen City, Guangdong Province, China

SZ Office: Room 2007, 20th Floor, Litong Building, No. 158 East Wuzhong Road, Wuzhong District, Suzhou City, Jiangsu Province, China

HF Office: Changjiang DoBe WE" International Hub, Luyang District, Hefei City, Anhui Province, China

Hotline: +86 021-61280216

E-mail: marketing@kengic.com

COPYRIGHT ©2018 KENGIC INTELLIGENT TECHNOLOGY CO.,LTD..All Rights Reserved. 鲁ICP备18025465号-1 Powered by:Hicheng

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.