Recently, KENGIC, an end-to-end intelligent and digital solutions provider for manufacturing and distribution across all scenarios, successfully completed a smart logistics and warehousing project for Ananda’s manufacturing facility in Tianjin. Ananda, a world-renowned expert in eDrive solutions headquartered in Shanghai, China, specializes in delivering high-performance electric drive systems.

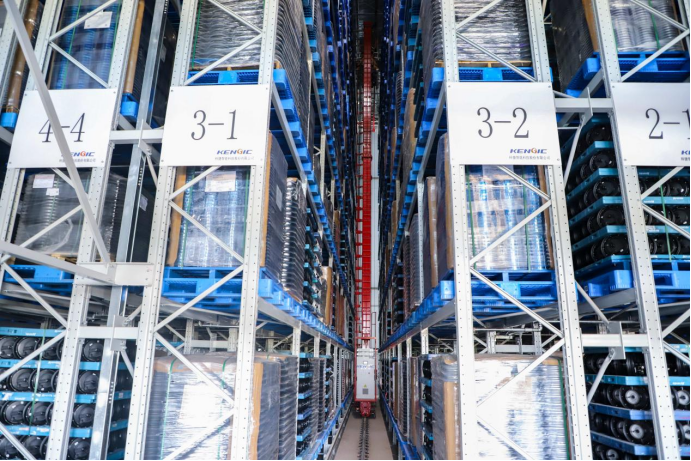

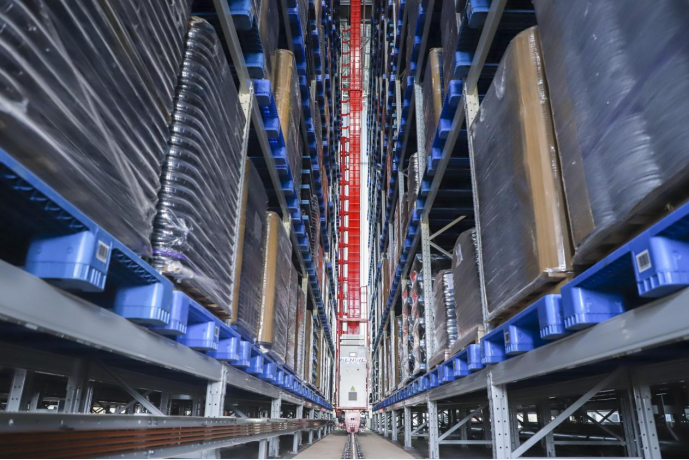

AS/RS Warehouse

The global electric two-wheeler market is experiencing an annual growth rate exceeding 17%. However, the industry faces significant challenges, including frequent order fluctuations, stringent quality control standards, and substantial inventory pressures, which are driving the transformation of traditional manufacturing practices.

SRM

In response to these challenges, Ananda sought tailored smart solutions from KENGIC. Consequently, KENGIC designed and implemented a highly integrated intelligent storage and logistics system for Ananda. At the heart of this system is an SRM AS/RS warehouse, seamlessly integrated with various advanced logistics technologies such as AGV handling (including forklift AGVs and latent jacking AGVs), CTUs (Carton Transfer Units), and automated conveyor lines. Through the coordinated operation of these intelligent systems, the entire workflow—from production lines, transportation, material shelving, storage, picking, to finished product outbound—has achieved automation and digital information management. This intelligent warehousing solution serves as a core enabler for the factory in enhancing operational efficiency and ensuring precise logistics management.

CTU

Mrs. Han, Deputy General Manager of Ananda Technology (Tianjin) Co., Ltd., said, "After adopting KENGIC’s smart storage and logistics system, Ananda’s automated warehouse is capable of managing order volumes that are 3 to 5 times higher than the average level. It now achieves a daily shipment volume of 20,000 units, with a product defect rate remaining below 0.001%."

The intelligent storage and logistics system has been deployed on the first and second floors of the factory. The first floor houses a raw material warehouse featuring 2,800 pallet storage positions and 19,000 tote storage positions within an automated warehouse system. Additionally, it manages the supply of empty pallets and the outbound logistics of finished products. The second floor is dedicated to the inbound and outbound handling of finished products, facilitated by automated guided vehicles (AGVs).

Forklift Robot

With the help of this system, the labor cost has been reduced by more than 50%, the space utilization rate has been increased by 200%, and the inventory accuracy has reached 99.99%. Various advanced technologies such as RGV handling and inbound, AGV handling for finished product outbound on the second floor, CTU robots inbound and outbound, latent jacking AGVs transportation, and AGV + CTU + intelligent scheduling system have realized the full-process automation.

Latent Robot

With the implementation of this system, Ananda has reduced labor costs by over 50%, improved space utilization in its factory by 200%, and achieved an inventory accuracy rate of 99.99%. The full-process automation has been realized through the integration of various advanced technologies, including RGV handling and inbound operations, AGV handling for finished product outbound on the second floor, CTU robot inbound and outbound functions, latent jacking AGV transportation, as well as the coordinated operation of AGV, CTU, and an intelligent scheduling system.

In terms of software, KENGIC's WMS/WCS system achieves seamless integration with Ananda’s ERP/MES systems, thereby ensuring the efficient and uninterrupted execution of the entire logistics process.

SRM+Conveyor Lines

This project, completed by KENGIC for Ananda, not only addresses the challenges encountered by traditional manufacturing in the rapidly evolving electric two-wheeler market but also establishes a benchmark for the whole manufacturing industry's intelligent transformation. It demonstrates KENGIC's strong capabilities in intelligent logistics and warehousing, and serves as a pivotal driver for advancing the modernization of the manufacturing sector.

We will reply you within 24 hours