Shanghai, China - 22nd, September - KENGIC, an end-to-end digital and intelligent solution provider for manufacturing and distribution across all scenarios, participated in the 23rd International Exhibition on Rubber Technology, held at SNIEC, Shanghai from 17th to 19th September. At the exhibition, KENGIC showcased its advanced integrated intelligent manufacturing solutions and industry-specific service philosophies tailored for the tire manufacturing sector, aiming to enhance operational efficiency and highlight the capabilities of China's intelligent manufacturing ecosystem.

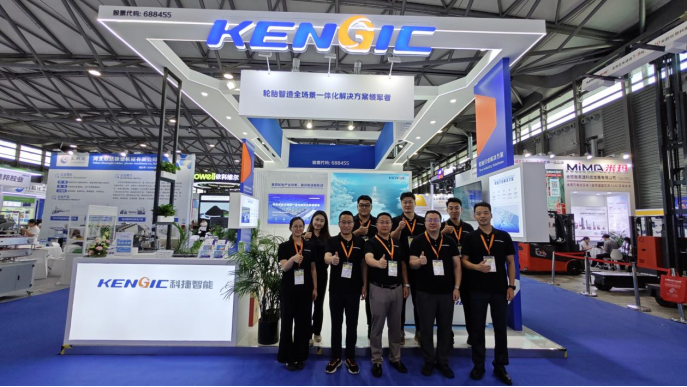

KENGIC Team at the 23rd International Exhibition on Rubber Technology

1. Cutting-Edge, Production-Critical Technological Innovations

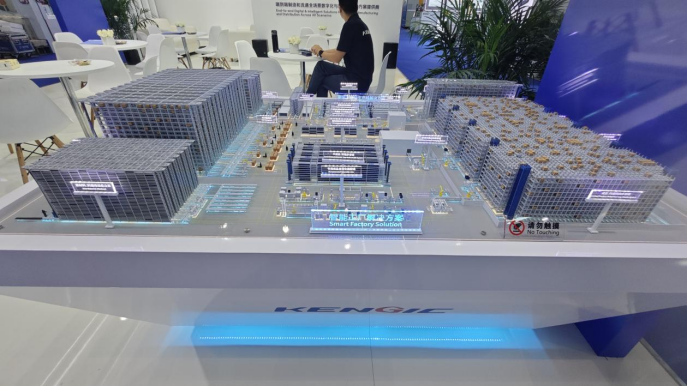

KENGIC’s Smart Factory Solution

KENGIC’s product lineup focuses on solving core challenges in modern tire production, with three flagship offerings standing out as industry enablers:

Advanced SRM System for Green Tire Storage: In contrast to generic storage solutions, this system is specifically designed for green tires (unvulcanized tires), which demand stringent environmental controls—including precise regulation of temperature and humidity—and non-damaging handling procedures to preserve product integrity. The system enhances storage space efficiency, minimizes human errors in inventory tracking, and enables full traceability of green tires throughout the production-to-vulcanization process. This capability is crucial for minimizing material waste and ensuring consistent, high-quality tire manufacturing outcomes.

EMS (Electrical Monorail System): As a material handling system based on an electrical monorail, the EMS addresses the inefficiencies and operational instability associated with traditional manual or fixed-track material transfer methods in tire manufacturing facilities. It facilitates flexible and automated transportation of semi-finished tires—such as those transferred from molding to vulcanization—across various production stages, while enabling real-time monitoring of material movement. By reducing material-handling delays, minimizing labor requirements, and enhancing the accuracy and timeliness of material flow, the system effectively mitigates production bottlenecks and supports seamless, continuous manufacturing operations.

High-Speed Gantry Robots: Designed for the high-volume, precision-driven needs of tire manufacturing, these robots excel in tasks like tire component handling, mold loading/unloading, and finished tire stacking. With high repeatability (reducing human-induced errors) and fast operation speeds, they significantly boost production throughput—addressing the industry’s demand for increased efficiency while maintaining strict quality standards. These robots are also adaptable to different tire sizes and production line layouts, ensuring compatibility with diverse client setups.

2. Client-Centric Solution Design: Aligned with Actual Needs

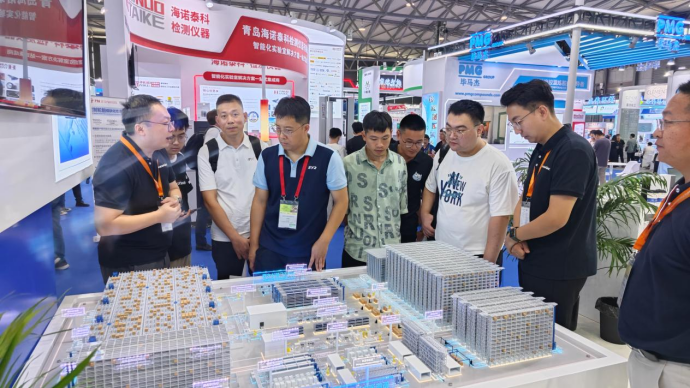

A steady stream of industry peers, customers, and curious visitors at the KENGIC booth

KENGIC’s product advantages extend beyond hardware/software performance, focusing on deep alignment with clients’ unique value chains:

Top-Tier Strategic Alignment: Every product and solution is designed based on a client’s corporate vision and project positioning. For example, if a tire manufacturer aims to expand its electric vehicle (EV) tire line (which requires stricter precision), KENGIC’s logistics and storage equipment can be calibrated to meet EV tire-specific storage and handling requirements, ensuring the solution supports long-term business expansion rather than just short-term operational needs.

Lean Process Optimization: Using tools like value stream mapping, KENGIC analyzes a client’s existing workflows to identify inefficiencies (e.g., redundant material transfers, delayed data sharing). This ensures the solution fits seamlessly into the client’s actual value chain, rather than forcing a one-size-fits-all approach.

3. Seamless Integration: Breaking Down Data and Operational Silos

A key differentiator is KENGIC’s ability to achieve end-to-end integration, a longstanding pain point in manufacturing:

Hardware-Software Synergy: Leveraging self-developed intelligent logistics and warehousing equipment, non-standard production lines, and configurable software, KENGIC eliminates compatibility issues common with third-party products. This synergy ensures smooth operation and reduces the time and cost of post-implementation integration.

OT-IT Integration via IIoT Platform: KENGIC’s self-developed IIoT platform bridges operational technology and information technology. This means data from the shop floor (e.g., tire production cycle time, equipment downtime) is automatically synced to IT systems, providing decision-makers with real-time insights to optimize production, reduce costs, and improve quality. For tire manufacturers, this integration translates to better visibility across the entire production lifecycle—from raw material intake to finished tire delivery.

4. Holistic Value: Beyond Technology to Ecosystem Support

KENGIC’s product advantages are underpinned by a holistic service philosophy that extends beyond product delivery. By positioning itself as a partner rather than a vendor, KENGIC supports the broader tire industry ecosystem—offering post-implementation training, maintenance, and updates to ensure its solutions continue to deliver value as clients’ needs evolve.

Ultimately, KENGIC’s mission is to create tangible value for clients by building automated, lean, and smart modern factories—driving cost reduction, efficiency improvement, and safe, high-quality production across the tire industry and beyond.

Looking ahead, KENGIC has already set its sights on the upcoming CeMat Asia in Shanghai this October, where it plans to connect with more industry players and showcase its latest advancements in smart logistics, smart warehouse, smart factory, new energy, smart software sectors among others.

We will reply you within 24 hours