Last month, we explored the types of businesses that benefit most from smart warehouse solutions at ‘Is Your Business Ready for the Smart Warehouse Revolution? Discover the 6 Types of Enterprises That Need It NOW’—ranging from e-commerce giants handling peak-order surges to manufacturers seeking streamlined inventory management.

Smart Warehouse

This month, we turn our attention to the backbone of every smart warehouse: the essential equipment that transforms traditional storage facilities into data-driven, high-efficiency hubs. For businesses considering this investment, understanding these core tools—many of which KENGIC specializes in—highlights both the value and practicality of upgrading.

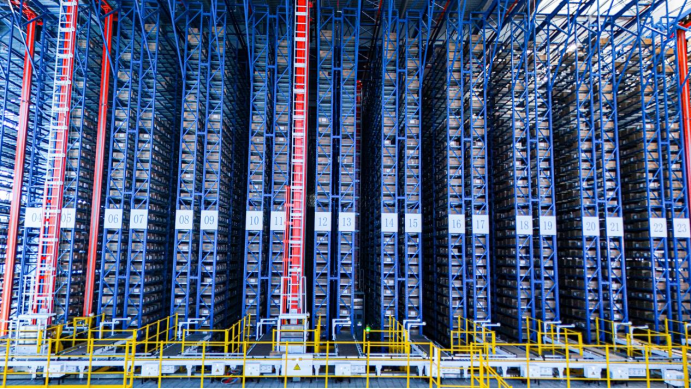

Automated Storage and Retrieval Systems (AS/RS)

AS/RS is a must-have for any smart warehouse. Unlike manual racking, AS/RS uses computer-controlled cranes, shuttles, and vertical lift modules to store and retrieve goods with minimal human intervention.

SRM

KENGIC’s AS/RS series is designed to operate along aisle tracks in high-rise warehouses—automatically storing goods into shelf compartments for inbound operations and retrieving them for outbound tasks. With manual, semi-automatic, and fully automatic modes, it adapts to different operational needs.

Our product line includes:

SRM series – the standard solution for versatile storage needs

Pallet SRM series – tailored for palletized goods

Thanks to its flexibility, KENGIC’s SRM is widely used across industries including logistics, automotive, new energy, tires, home furnishings, home appliances, pharmaceuticals, food, chemicals, and cold chain.

Material Handling Equipment

Efficient movement within the warehouse depends on advanced handling systems such as gantry robots, autonomous guided vehicles (AGVs), and autonomous mobile robots (AMRs). These solutions reduce reliance on forklifts, cut labor costs, minimize accidents, and accelerate operations.

Gantry Robot

KENGIC’s Gantry Robot is especially valuable for industries like tire manufacturing, where heavy-duty, high-precision handling is required. It addresses common pain points such as inefficient manual palletizing, high labor costs, and inconsistent accuracy.

Multi-Shuttle Systems

For high-density, high-efficiency environments—such as e-commerce fulfillment centers, pharmaceutical warehouses, cold-chain storage, and apparel hubs—KENGIC’s Tote/Pallet Multi-shuttle System offers unmatched flexibility and throughput, redefining order-handling efficiency.

Pallet Four-way Shuttle System

Automated Sorting and Conveying Systems

Sorting and conveying are critical for processing large order volumes quickly. Traditional manual sorting often leads to bottlenecks during peak periods, but KENGIC’s advanced systems eliminate these inefficiencies.

Our offerings include:

Sorters: cross-belt sorter, loop cross-belt sorter, 3D sorter, vertical narrow-belt sorter, steerable wheel sorter, one-carrier two-belt cross-belt sorter, and linear cross-belt sorter

Conveyors: carton conveyor, pallet conveyor, roller conveyor, belt conveyor, etc.

Together, they process massive item volumes per hour with up to 99.8% accuracy, enabling faster, more reliable order fulfillment.

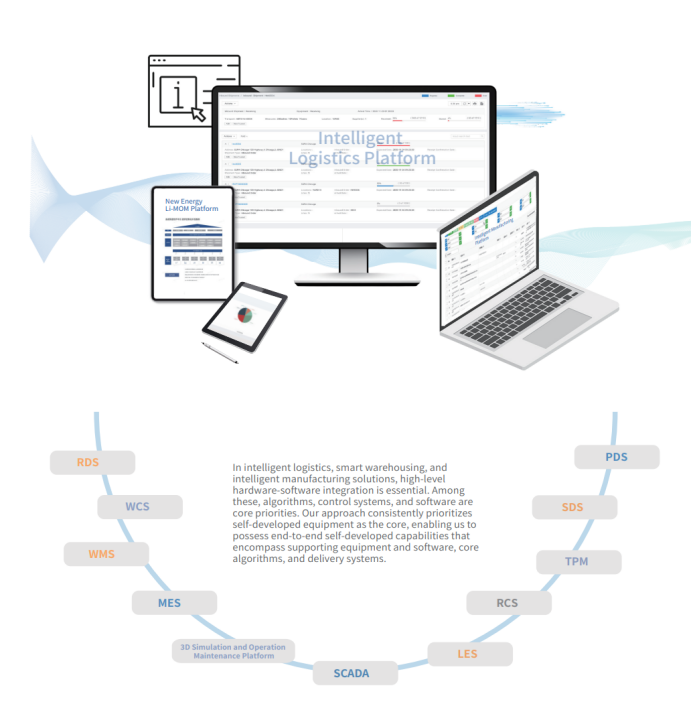

Sensing and Identification Technologies

Smart warehouses rely on real-time data. RFID tags and readers allow accurate tracking of goods throughout the supply chain. Integrated with KENGIC’s software products such as RDS, WCS, WMS, MES, 3D Stimulation and O&M Platforms, SCADA, LES, RCS, TPM, SDS, PDS. etc. these technologies provide full visibility of stock levels, item locations, and order statuses—empowering smarter, data-driven decisions.

KENGIC’s Software Products

Warehouse Management System (WMS)

At the heart of it all is the WMS—the brain of the smart warehouse. KENGIC’s cloud-based WMS integrates every piece of equipment into a unified ecosystem. It:

Schedules tasks for AS/RS, AGVs, and sorters

Provides analytics on KPIs such as inventory turnover, order fulfillment rates, and equipment downtime

Supports real-time collaboration with logistics partners

Customizes functionality for specific industry needs (e.g., cold chain, hazardous materials, reverse logistics)

WMS

Clients leveraging our WMS have seen up to 20% lower inventory holding costs and 15% faster on-time deliveries—clear proof of its efficiency-driving capabilities.

Building the Future of Warehousing

Investing in a smart warehouse is more than purchasing equipment—it’s about creating a connected, intelligent system aligned with your business goals.

KENGIC’s end-to-end solutions scale with your growth, whether you’re a small retailer entering e-commerce or a multinational manufacturer optimizing global supply chains.

For customized solutions, contact us at marketing@kengic.com or visit www.kengic.com. With the right equipment, backed by our technical expertise and after-sales support, you can transform your warehouse into a competitive advantage—reducing costs, improving customer satisfaction, and future-proofing your logistics operations.

We will reply you within 24 hours