KENGIC, an end-to-end digital and intelligent solutions provider for manufacturing and distribution across all scenarios, will make a powerful appearance at CeMAT ASIA 2025 from October 28th to 30th. With the theme “Innovating Together, Shaping the Future of Smart Logistics,” KENGIC will showcase its next-generation logistics systems, latest Digital Factory Solutions, and green manufacturing technologies, demonstrating how innovation, digitalization, and sustainability are driving the new industrial era.

Smart Logistics Redefined

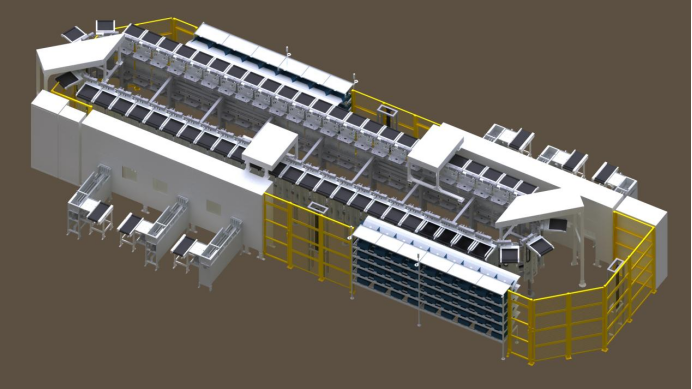

At the heart of KENGIC’s showcase is its full lineup of logistics automation systems, including the Automatic Package Collection System, 3D Sorter, EMS, and AirRobot.

3D Sorter

The Automatic Parcel Consolidation System optimizes e-commerce and express logistics with single-operator multi-chute management, reducing labor intensity through RFID tracking

and DotNetty-based WCS data processing.

Breaking horizontal limitations, the 3D Sorter integrates vertical lifting and horizontal delivery, doubling order processing efficiency with enhanced space utilization.

The EMS boasts 270m/min speed, 120kg load capacity, and ±2mm positioning accuracy, suited for automotive, semiconductor, and food sectors.

Complementing it, the AirRaobot offers cost-effective high-density storage for light goods under 30kg.

Together, these systems represent a new benchmark for intelligent, flexible, and high-density material handling.

Building the Future: KENGIC Digital Factory Solution

Besides the smart logistics solutions, KENGIC will debut its digital factory solution, which centers on Digital Twin System, a real-time intelligent platform that integrates data from the execution, control, and equipment layers to achieve full-process transparency. The system supports visualization, device management, data governance, permission control, and inventory management—empowering factories with predictive maintenance, quality traceability, and dynamic resource optimization.

Digital Factory Solution

From the factory-level dashboard that monitors safety, efficiency, and production KPIs, to workshop and production-line views showing OEE, energy usage, and real-time alarms, the system enables comprehensive, multi-layer digital management—pushing Industry 4.0 transformation forward.

KENGIC’s Green and Energy-Saving System of the digital factory solution further strengthen its commitment to sustainability. Spanning energy recovery, efficiency optimization, IoT-based monitoring, and environmental protection, these solutions incorporate motor energy control, photovoltaic energy storage, heat recovery systems, and waste treatment modules—building an eco-friendly, smart manufacturing ecosystem.

The TPM Equipment Management System serves as the “health report” of automated equipment such as SRMs. It captures real-time operational data, tracks downtime, alarms, and maintenance records to enable preventive maintenance and ensure reliable performance.

In addition, the AI-based Visual Inventory System utilizes 2D/3D cameras and deep learning algorithms to automate inventory checks—achieving counting speeds of up to 5 seconds per pallet with high precision. This system enhances efficiency, reduces manual effort, and provides accurate real-time inventory control.

Engage and Explore

Visitors can expect more than innovation—interactive booth experiences such as lucky draws and quiz games will bring surprises and prizes throughout the event.

Join KENGIC at CeMAT ASIA 2025 to explore how intelligence, flexibility, and green innovation converge to empower the next generation of smart factories and logistics. Let’s meet at Booth I4, Hall W4 of Shanghai New International Expo Center!

We will reply you within 24 hours