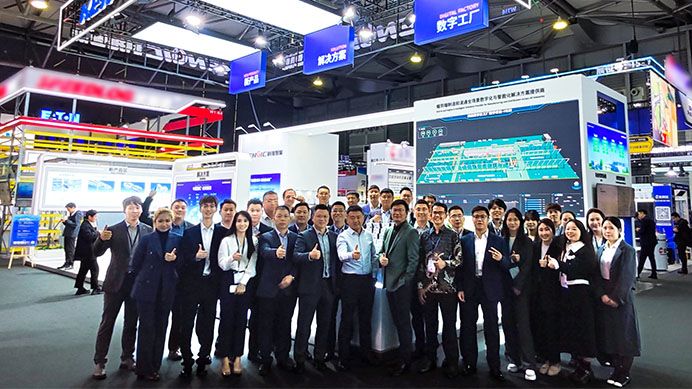

Shanghai, China— KENGIC, an end-to-end digital and intelligent solutions provider for manufacturing and distribution across all scenarios, made a powerful appearance at CeMAT ASIA 2025, held from October 28th to 30th in Shanghai. The company concluded its successful exhibition with a series of cutting-edge innovations that highlighted the future of smart logistics and manufacturing.

Under the theme “Innovating Together, Shaping the Future of Smart Logistics,” KENGIC demonstrated how innovation, digitalization, and sustainability are transforming the industrial landscape. Visitors were invited to experience a comprehensive lineup of next-generation Digital Factory Solutions, intelligent logistics systems, and green manufacturing technologies—all designed to enable a smarter, more efficient, and sustainable industrial future.

KENGIC Team at CeMAT Asia 2025

[Watch the recap video to relive the highlights of KENGIC at CeMAT ASIA 2025.]

[Also check out “Yoyo’s Booth Tour” — a lively walkthrough video where Yoyo explores KENGIC’s key solutions, interactive displays, and exciting booth moments from the exhibition floor.]

At the heart of the booth stood the KENGIC Digital Twin System, the “brain” of the Smart Factory. Operating seamlessly across four levels—factory, workshop, production line, and equipment—the system provides real-time visibility into performance, energy consumption, safety, and quality metrics, empowering managers to make informed decisions from a single integrated dashboard.

KENGIC Digital Twin System

Yet, as KENGIC emphasizes, a truly intelligent factory requires not only a brain, but also a green heart and a strong body. The KENGIC Green Energy-saving Solution embodies this vision by addressing four key areas: resource recovery, energy saving, data collection, and environmental protection. Successfully applied in more than 15 real-world scenarios, it demonstrates KENGIC’s commitment to sustainable industrial development.

KENGIC Green Energy-saving Solution

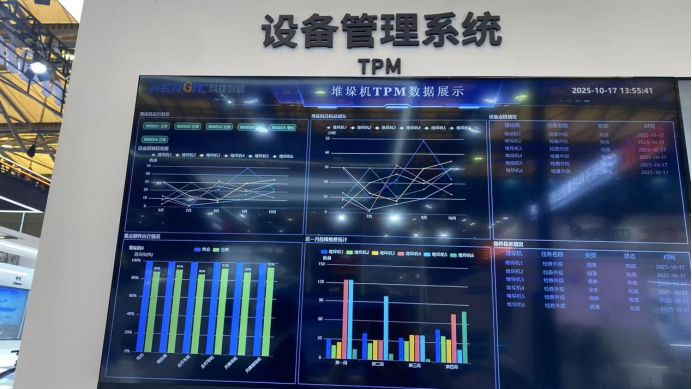

Complementing this is the TPM Equipment Management System, often referred to as the “health report” of machinery such as SRMs. By continuously monitoring equipment status, predicting failures, and optimizing maintenance schedules, it minimizes unplanned downtime and enhances production stability.

KENGIC TPM Equipment Management System

The AI Visual Inventory System further expands KENGIC’s smart capabilities, using 2D and 3D vision with deep learning to identify and count packages in just five seconds per pallet—enabling precise, efficient, and automated inventory control.

KENGIC AI Visual Management System

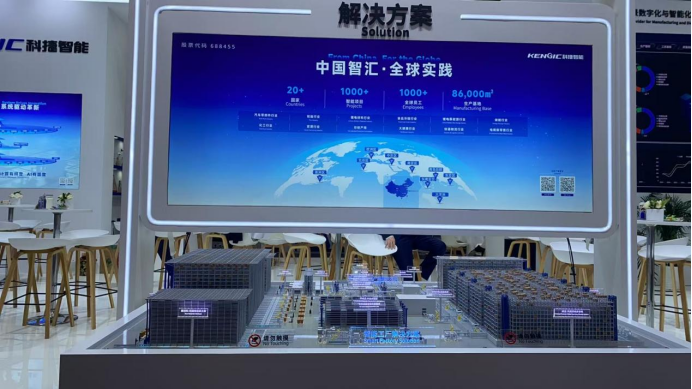

At the KENGIC Solution Zone, visitors discovered how these technologies empower diverse industries including express logistics, e-commerce, automotive, and healthcare. The end-to-end Smart Factory Model brought this integration vividly to life—demonstrating the complete journey from raw material storage and semi-finished product handling to automated packaging and outbound shipping.

KENGIC Smart Factory Model

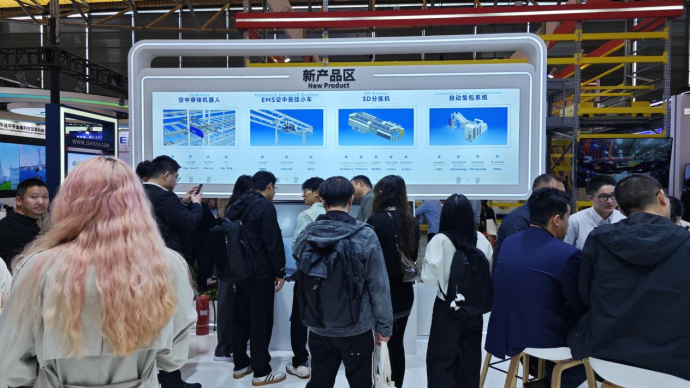

Meanwhile, in the New Product Zone, KENGIC unveiled its latest breakthroughs in logistics automation: AirRobot, Electrical Monorail System (EMS), 3D Sorter, and Automation Assembly Packaging System. Together, these innovations showcased the company’s forward-thinking approach to air–ground collaboration and efficiency enhancement.

KENGIC’s Latest Breakthroughs

Beyond product showcases, Mr. Xiong, Director of Pre-sales Planning, Smart Factory BU, delivered an inspiring speech titled “Global Strategies, Boundless Intelligent Manufacturing – Digital Factory Implementation Experience Sharing.” In addition, KENGIC executives engaged in exclusive media interviews, sharing their insights on global market trends, innovation strategies, and the future of intelligent manufacturing.

KENGIC Executives Insights Sharing

KENGIC’s leadership and innovation were further recognized through multiple industry awards, reaffirming its prominent position in the fields of smart logistics and manufacturing.

KENGIC’s Awards

Adding to the excitement, the booth’s interactive activities and games created an energetic and engaging atmosphere, drawing enthusiastic participation from global visitors.

As Mr. Xiong concluded, “At KENGIC, we are not just imagining the future—we are building it through advanced technologies, proven global experience, and professional local service teams.”

With strong momentum and vision, KENGIC will continue to drive global innovation in smart logistics and intelligent manufacturing. We are looking forward to meeting you all again at Manufacturing from 3rd to 6th December, where we will bring even more smart logistics and automation innovations to share.

We will reply you within 24 hours