The year 2025 marks a major shift in intralogistics. For years, the global market has been divided: standard automation became common, while complex solutions, like heavy-duty gantries and aerial robotics, stayed the domain of a few large international companies.

This year, that story changes.

With strong R&D and significant project launches across industries, KENGIC has introduced and upgraded a 2025 technology portfolio that not only meets global standards but also sets them in many sectors.

Here is Part 1 of our exploration into the technology shaping the future of the supply chain.

1. The Heavy-Duty Pallet Four-Way Shuttle

The Market Gap: Worldwide, the market for standard pallet shuttles is crowded. However, true industrial-grade, heavy-load shuttles that can work in tough chemical or extreme temperature settings are uncommon.

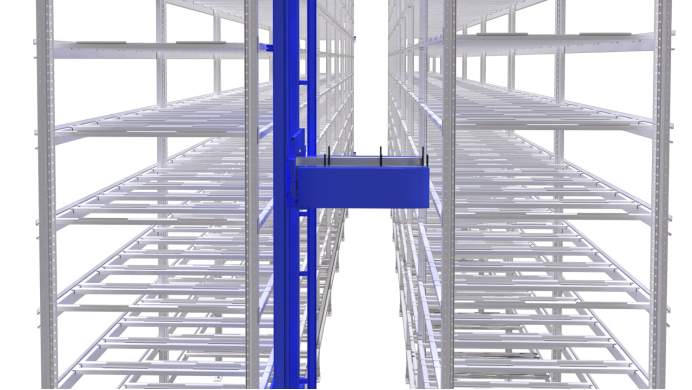

Pallet Four-way Shuttle System

The KENGIC Solution:

Our 2025 Pallet Four-Way Shuttle directly addresses this gap. Tailored for demanding projects, like the chemical initiative, this system is built to last.

Power & Capacity: With a rated load of 1500kg, it manages loads that can stall lesser machines.

Versatility: Available in Hydraulic Versions (for heavy loads) and Mechanical Versions (for speed), it suits specific warehouse needs.

Precision: Despite its power, it achieves a positioning accuracy of ±2mm, ensuring smooth transfer in high-density storage.

By refining this technology for heavy industry, we have developed a flagship product with almost no direct competition in the current market.

2. The Fly Shuttle: A Category of One

The Market Gap: Traditional "Miniload" systems are inflexible. While some suppliers are looking into aerial shuttles, the technology is often new, and few competitors have a comparable, mature product.

Fly Shuttle system

The KENGIC Solution:

The Fly Shuttle system is a breakthrough in 3D logistics. It moves beyond fixed tracks into a smart, multi-axis ecosystem.

Visual Navigation: This system uses a Visual Operation Panel and advanced algorithms for positioning, addressing the industry-wide issue of 2D positioning accuracy.

Efficiency: It can handle totes and cartons weighing up to 30kg, combining storage and sorting in one step.

Synchronized Motion: The four-wheel synchronization guarantees smooth and stable movement even at high speeds.

This is not just an improvement; it’s a new type of automation that paves the way for updating older warehouses where floor space is tight, and rebuilding is not feasible.

3. Gantry Robots: Breaking the Oligopoly

The Market Gap: High-speed, heavy-load Gantry Robots have long been limited to a few large companies. Vendors have struggled to match the speed, load capacity, and precision necessary for top-tier manufacturing.

KENGIC Gantry Robot

The KENGIC Solution:

With our Heavy-Load High-Precision Gantry Robot, we have proven that the monopoly is over.

Heavy Lifting: Our heavy-duty models can handle loads of up to 2000kg with ease.

Excellent Precision: Despite the heavy load, we achieve an action accuracy of 1mm.

Global Validation: Successfully deployed in sorting and stacking tasks of our worldwide benchmark projects, these robots provide "Flexible Control" and "Large Working Radius" that rival the best European systems.

Whether it’s the High-Speed version for fast sorting or the Heavy-Load version for industrial assembly, KENGIC gantry robots now present a credible, high-performance alternative to traditional Western suppliers.

(Continued in Part 2: High-Speed Sorting and Specialized Industry Solutions...)

We will reply you within 24 hours