In Part 1, we explored how KENGIC is redefining heavy-load handling and aerial robotics. In Part 2, we focus on high-speed throughput, niche industry integration, and solving the "First Mile" bottleneck.

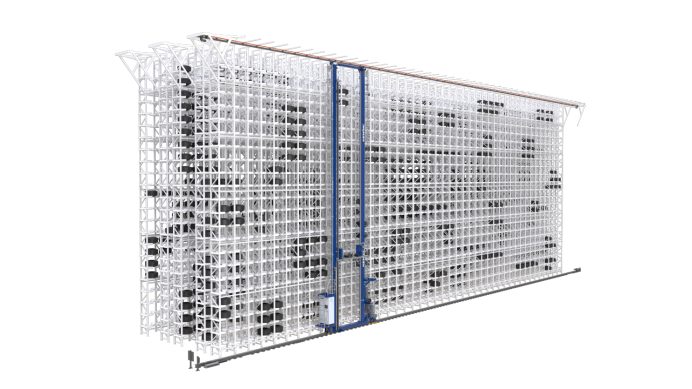

4. The Tote Four-Way Multi-Shuttle: The Efficiency Engine

The Market Gap: Many suppliers offer tote shuttles, but few provide the reliability needed for massive e-commerce throughput.

Tote Four-way shuttle

The KENGIC Solution:

Our Tote Four-Way Shuttle meets the high-speed demands of modern commerce.

Throughput: One workstation can process up to 900 order lines per hour, making it 3-5 times more efficient than traditional versions.

Agility: With seamless switching between 5G and Wi-Fi, along with energy recovery technology, these units are built for 24/7 operation.

Density: Supporting both "Single-deep" and "Multi-deep" storage, it maximizes every cubic meter of warehouse space.

5. Specialized Integration: SRM for Green Tire Storage and EMS

The Innovation:

Beyond general logistics, KENGIC has developed industry-specific solutions.

SRM for Green Tire Storage: This Stacker Crane features dual-motor synchronous control and anti-sway technology, designed for the delicate yet heavy nature of green tires in the automotive sector.

SRM for Green Tire Storage

EMS Systems: From Basket-type EMS to Gripper-type EMS, we have addressed gaps in our field, showing our ability to provide complex, suspended transport systems internationally.

KENGIC EMS

6. The Automatic Cage Inverting Equipment: Solving the "First Mile" Bottleneck

The Market Gap: In high-speed logistics and e-commerce hubs, sorting lines operate quickly, but the feeding process remains slow and requires a lot of labor. Manually unloading heavy roll cages creates a throughput bottleneck and poses safety risks.

KENGIC Automatic Cage Inverting Equipment

The KENGIC Solution:

Our Automatic Cage Inverting Equipment automates the chaotic "injection" phase of logistics. It is a smart system that uses vision guidance to replace manual labor.

Vision-Driven Intelligence: Unlike basic mechanical dumpers, it employs Vision Algorithms to monitor cargo flow, detect stoppages, and adjust the inverting speed to prevent jams.

Universal Compatibility: With One-Key Switching, it fits various sizes of cage carts. The system links the cargo type to the dumping angle for different items.

Labor and Safety Revolution: The Fork-Type Cage Support System removes the need for manual pushing of heavy cages up ramps. Paired with an Electric Cylinder Gripper for auto-alignment, it ensures efficient throughput and lowers labor intensity.

Our Edge: While competitors focus on storage systems (AS/RS), KENGIC manages the warehouse entry point, providing an end-to-end automated solution.

The Verdict: Ready for the World

In 2026, KENGIC will transition from being a leader in China to a challenger on the global stage.

We have progressed beyond simple manufacturing. By using EPLAN Propanel for standardized electrical design and making advancements in visual navigation and heavy-load handling, we have built a strong, compliant, and innovative technology stack.

From the heavy-duty aisles of chemical plants to the fast operations of the Fly Shuttle, KENGIC is prepared to deliver the future of intelligent logistics globally.

We will reply you within 24 hours

No. 132-1, 201, Gao Yi Road, Gaoyang City, Gyeonggi Province, Republic of Korea

QD HQ (North China): No. 21, Jinye Rd, High-tech Zone, Qingdao City, Shandong Province, China

SH Branch (East China): Building 23, Libo Business Center, Lane 379, Hongmei South Road, Minhang District, Shanghai City, China

CD Office (Southwest China): Room 2103, Taizhoushangren Building, Zhaojue Temple, No. 80 Heng Road, Chenghua District, Chengdu City, China

GZ Office (South China): Room 2112, Yanqiao Building, No. 89 Yanling Road, Tianhe District, Guangzhou City, Guangdong Province, China

SZ Office (South China): Room B1, 13th Floor, Building 12, Lehui Science and Technology Innovation Center, No. 489 Jihua Road, Bantian Sub-district, Longgang District, Shenzhen City, Guangdong Province, China

SZ Office: Room 2007, 20th Floor, Litong Building, No. 158 East Wuzhong Road, Wuzhong District, Suzhou City, Jiangsu Province, China

HF Office: Changjiang DoBe WE" International Hub, Luyang District, Hefei City, Anhui Province, China

Hotline: +86 021-61280216

E-mail: marketing@kengic.com

COPYRIGHT ©2018 KENGIC INTELLIGENT TECHNOLOGY CO.,LTD..All Rights Reserved. 鲁ICP备18025465号-1 Powered by:Hicheng

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.