- HOME

- ABOUT US

- SOLUTION

- PRODUCT CENTER

- CASE CENTER

- NEWS

- INVESTOR RELATIONS

- CONTACT US

- JOIN KENGIC

As one of the important areas of new infrastructure construction, vigorously developing urban rail transit and comprehensively guaranteeing supporting industries are an effective way to build a green, safe and smart city.

As an important branch and supporting industry of the rail transportation equipment industry, rail transit air-conditioning has ushered in a historic opportunity to achieve high-quality development with the benefit of new infrastructure and intelligent, and the market scale is growing rapidly.

Founded in 2000, Shandong Longertek Technology Co., Ltd., is committed to the R&D and promotion of air-conditioning and variable-frequency energy-saving air-conditioning technology for rail transit vehicles. It is the company in the industry that has internationally advanced variable-frequency energy-saving core technology, refrigeration system control technology and big data intelligent maintenance technology. As a leading company in my country's rail transit inverter air conditioner industry, its market share is increasing year by year.

In 2020, KENGIC Intelligent and Longertek Technology have reached a strategic cooperation. Both parties will implement the national intelligent manufacturing 2025 policy orientation and the German Industry 4.0 target requirements, and in-depth exchanges and comprehensive cooperation in digital R&D, digital manufacturing, digital supply chain and digital life cycle management.

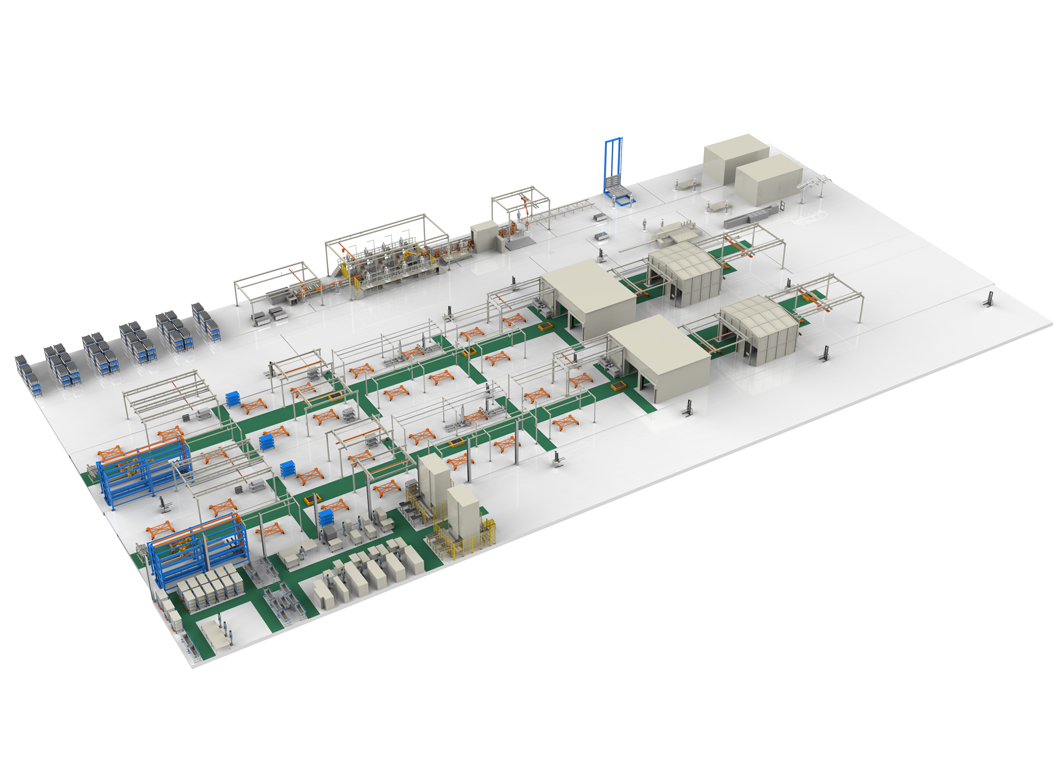

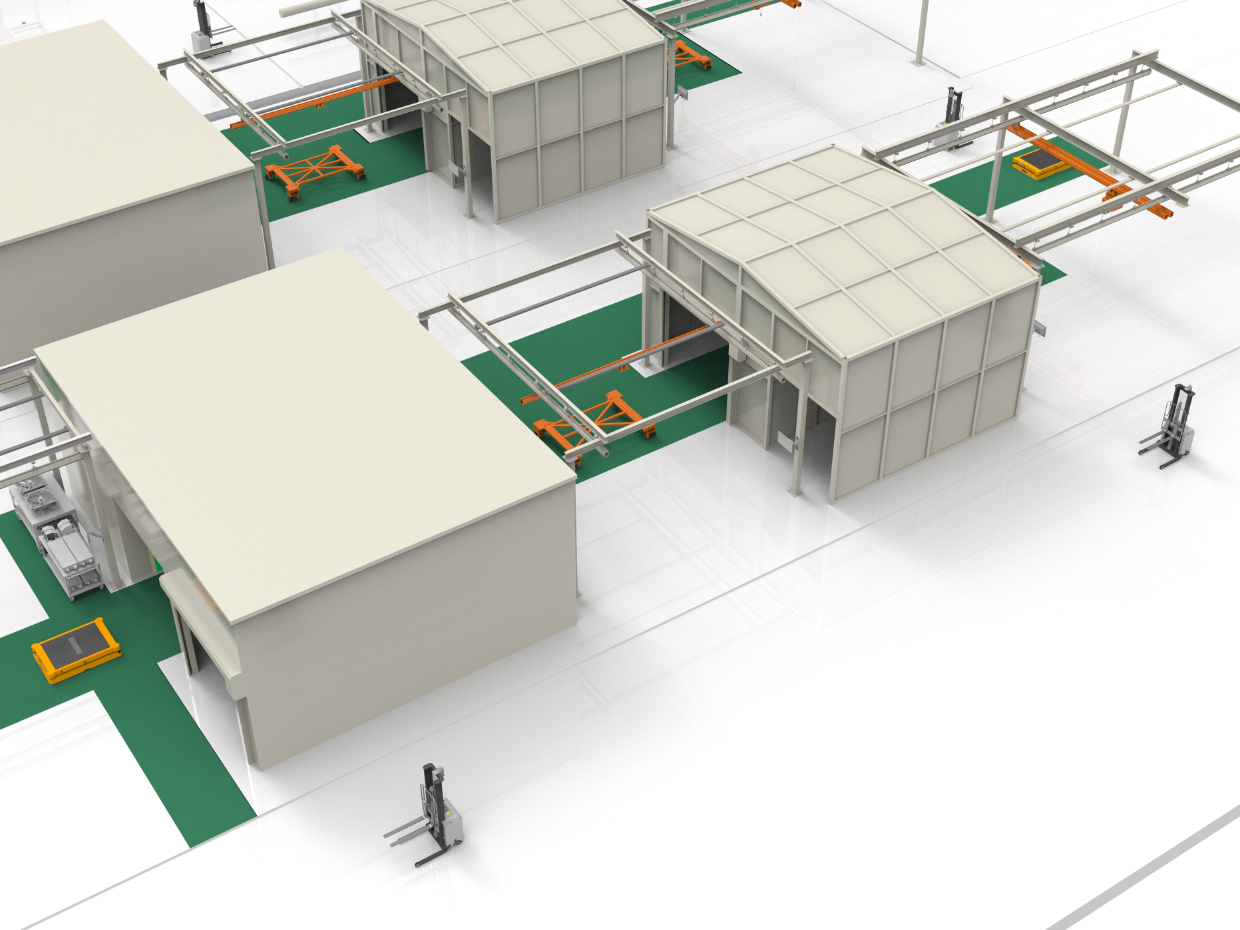

KENGIC Intelligent has built a complete set of digital factory construction solutions to provide comprehensive solutions, technologies, products and services for the rail air-conditioning assembly and related support workshop infrastructure, product production equipment, automated logistics system, process IT construction and project general contract implementation, etc. Jointly build a national/provincial/municipal rail air-conditioning industry digital manufacturing demonstration project.

In the first phase of the rail air-conditioning assembly line project of the digital factory construction, the intelligent manufacturing team of KENGIC intelligent builds customized CRM, SCM, MES, WMS through four levels of product analysis, target planning, overall plan design, and implementation of each station plan. Using the multi-station flexible layout of resource collaborative distribution and route optimization methods, the end-to-end business horizontal integration of Longertek Technology and the vertical integration of enterprise internal data to realize the flexibility, transparency, visualization, and intelligence of the rail air-conditioning production process to achieve operation platformization, operation and maintenance services, and intelligent decision-making, then opened demonstration applications for digital factories in the rail air-conditioning industry.

Phase I Digital factory construction rail air-conditioning assembly line

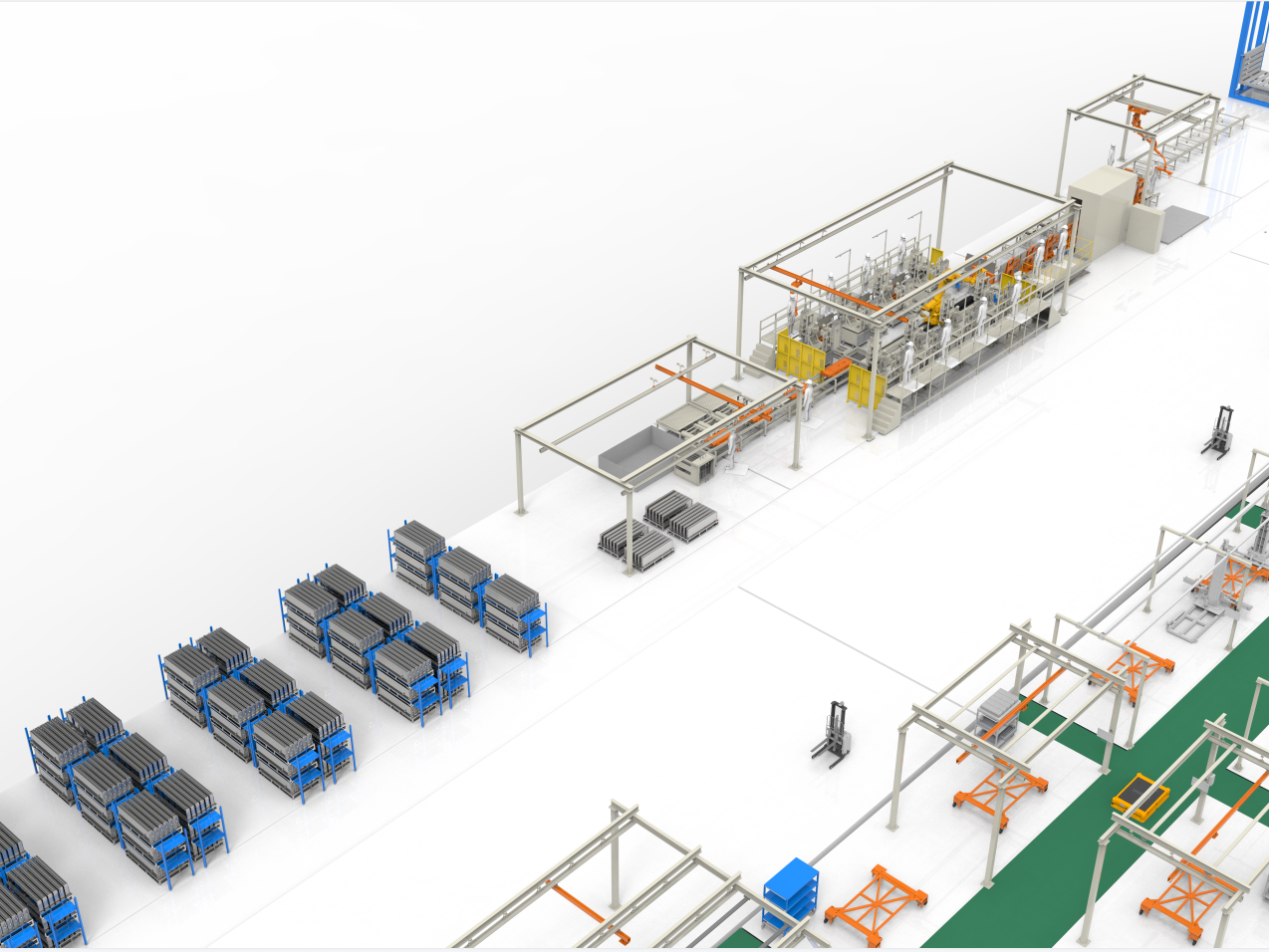

According to the planning of the A/B/C three types of product principles and indicators of the project, through comprehensive consideration and rigorous calculation of working hours, work rhythms and actual production requirements, on the basis of reasonable matching of labor, the A-type capacity increased by 65%, the B-type production capacity increased by 60%, and the C-type production capacity increased by 65%, ensuring the reliability and stability of product performance, responding to market demands faster and better, and helping Langertek Technology build an industry-leading benchmark enterprise.

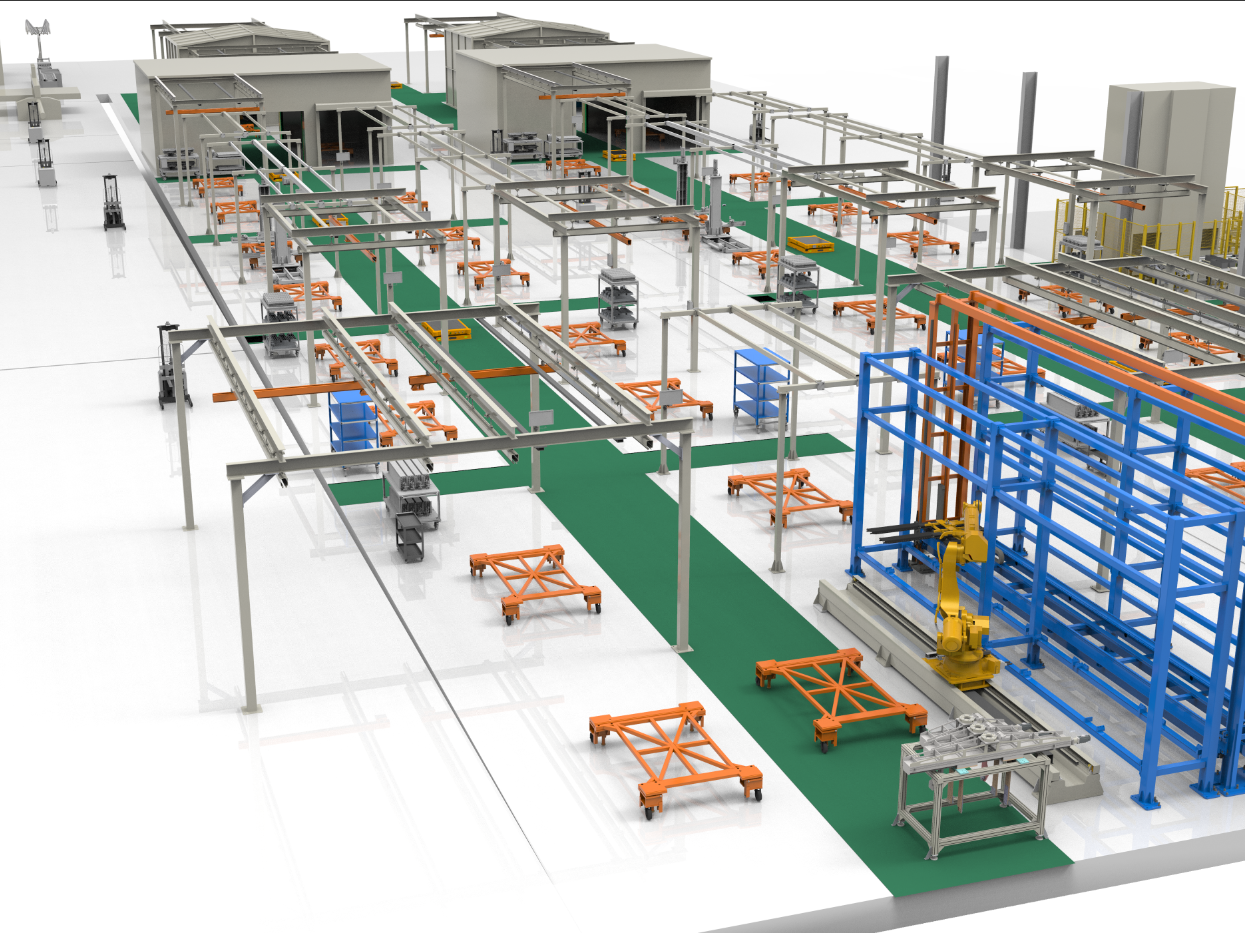

Automated assembly line

1. AGV replaces the floor chain to realize flexible production;

2. Robot + vision technology for large-piece assembly to reduce the intensity of manual work;

3. The MES system realizes the optimal allocation of manufacturing resources in the whole assembly.

Automated logistics line

1. AGV replaces manual forklifts and trolleys, and realizes the automatic distribution of materials required for assembly from the material buffer area to the assembly station area;

2. The robot station single material fixed-point distribution is combined with the manual station multi-material assembling distribution.

Informatization and network construction

1. Construct information systems represented by MES, SCADA, WMS, etc., to realize order issuance, plan execution, material distribution, tracking, error prevention, process curing, equipment monitoring, important data collection, worker management, energy monitoring and other functional modules to meet full life cycle management of customers and products, self-diagnosis and maintenance of equipment;

2. The production data and inspection data of automation equipment and quality control methods can be collected, diagnosed, and traceable;

3. The pallet is equipped with RFID, and the production program is automatically switched according to the scan code to confirm the production procedure when multiple different product lines work at the same time

4. The 5G workshop is fully covered, compatible with existing systems, breaking application islands, and enabling production flow, full life cycle flow, and production value flow.

Assembly design and process optimization

1. Through the collaboration of design, process, and production line operators, a series of optimization suggestions are proposed according to DFA design guidelines, actual design experience and assembly operation practices in the loading, filming, assembly, welding, testing, raining test and material distribution section.

2. Simplify the assembly process, shorten assembly time, reduce assembly errors, improve assembly quality, and reduce assembly defects, thereby increasing assembly productivity and personnel efficiency.

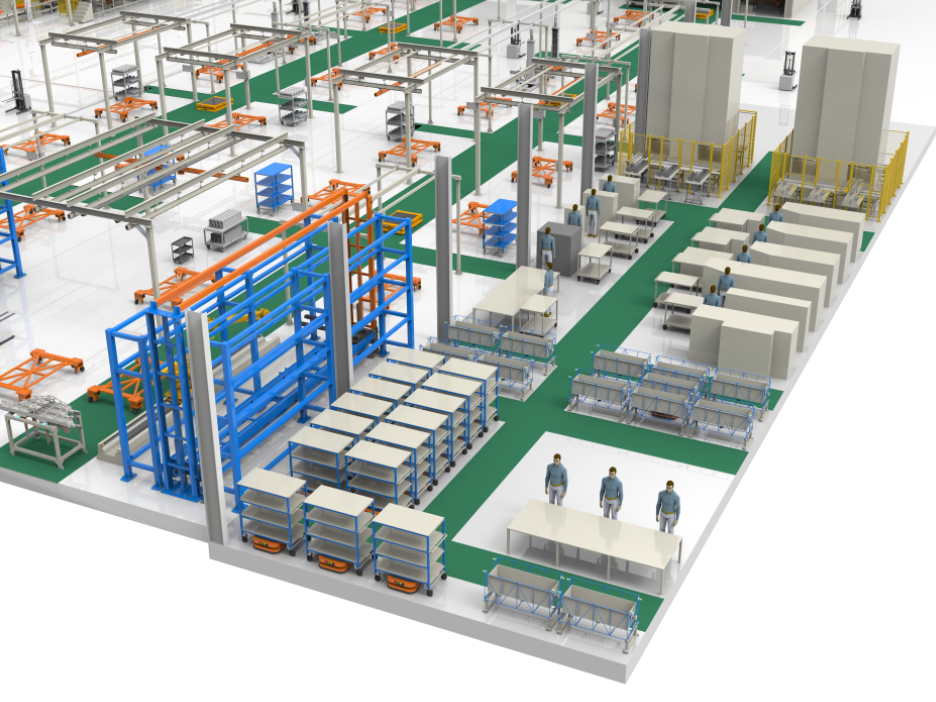

Lean production and flexible production

1. Standardized operation: balance the cycle of each work station and optimize the layout of the production line through the consolidation of work stations, standardized work of fixed positions and fixed staff;

2. Flexible operation: compatible with accompanying tooling, independent tooling station layout;

3. The Andon alarm system is set for the whole line: When there is an operating problem, the line body is suspended, or the fault occurs, the Andon is manually pressed to alert the whole line to warn the whole line. AGV can quickly remove the problem station from the main line, so that the technicians can deal with it in time without affecting the main line operation;

4. Promote production: the production line is equipped with station kanbans and the workshop is equipped with workshop big kanbans to realize paperless production process guidance and transparent production plans.

The construction of this project is an important step for Langertek Technology to build a digital factory, and it is also an important landing for the company to achieve the goal of intelligent manufacturing.

With the power of intelligent manufacturing, KENGIC Intelligent helps rail transit and its supporting industry enterprises to achieve lean management, improve overall operating efficiency, reduce design and manufacturing resource cost input, promote the improvement of operating efficiency, and provide support for the long-term development of enterprises and industries. Provide guarantee for the construction of smart urban rail and transportation power!

We will reply you within 24 hours