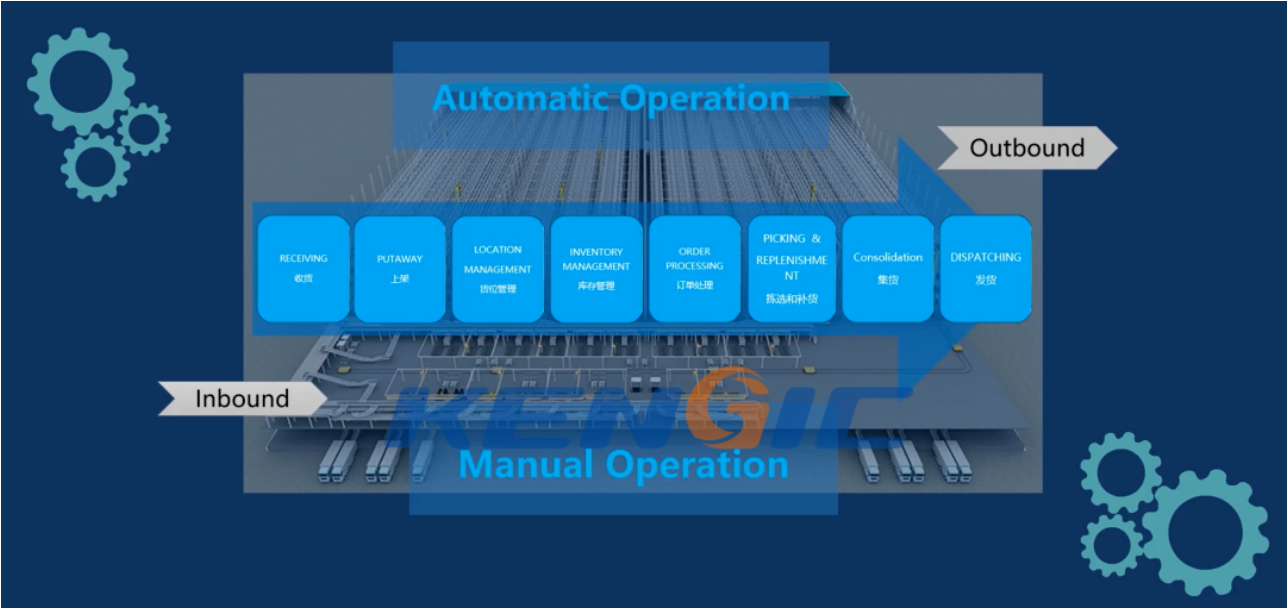

WMS,(Warehouse Management System), which is a comprehensive management system including functions such as inbound management, inventory management, outbound management, and advanced management. Inventory operations can be performed independently, and other systems can also be used in combination to provide enterprises with more complete and detailed logistics supply chain management processes and decision-making reference information.

Like building blocks, the WMS system has rich functions and complete processes, and can be configured with one or more warehouses for management. In a warehouse, one or more buildings can be configured; in one building, one or more areas can be configured; in one area, one or more storage spaces can be configured.

In actual use, it can be used for warehousing process, appointment management, receiving palletizing, quality inspection management, shelf management, outbound process, wave management, inventory allocation & off-shelf, picking, review packaging, goods collection & delivery, inventory Management, inventory management and other process steps are tailored and configured to meet the actual business needs of different customers with high cost performance.

Core Competencies of WMS

Operational whole process tracking

Refined Inventory Management

The process can be flexibly configured

Highly transparent of inventory and process

Optimize process planning and operation execution

Improve the overall operational efficiency of the warehouse

The logistics supply chain is a complex organic whole, involving many subjects and complex business processes, requiring seamless, real-time, and dynamic business data collaboration among multiple subjects, which can be understood as the range from product or market demand to meeting demand of the chain formed by all the logistics activities involved in it.

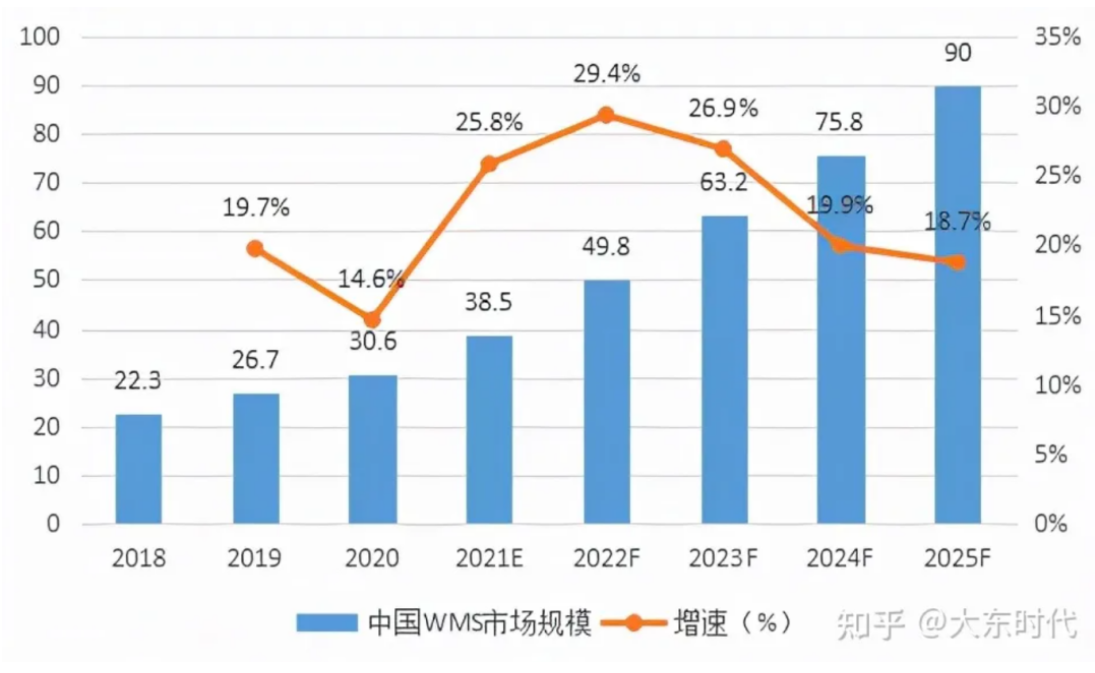

Refrencese: Organized by Dadong Times (TD)

Refrencese: Organized by Dadong Times (TD)Supply chain pain points faced by enterprises

Warehouse mode urgently needs to be updated

Flat library storage, low effective space utilization

The data is inconsistent with the actual inventory

Many people work at the same time, lack of efficient and unified platform information management

Logistics reconciliation relies on paper documents

Inconsistent clearing data, low efficiency and long cycle

Work efficiency can not keep up

Manual operations in traditional warehouses lead to inefficiencies and restricted working environments

High error rate

Lack of an effective system for fault-tolerant control

Inventory overstock cost problem

Uncertainty exists in manual operations, and it is prone to a series of problems such as delays in inventory updates, inaccurate quantities, delivery of wrong goods, difficulties in first-in-first-out implementation, excessive sluggish materials, difficulties in traceability, and difficulties in performance management, which will increase storage costs.

Customized WMS empower the supply chain level

As a system solution provider, KENGIC provides a full range of integrated supply chain planning and execution solutions, from procurement, transportation to production, covering supply chain management, raw material management, finished product management and sales, assisting customers to break through one by one Business pain points!

Inbound Manage

Onbound Manage

Wave Manage

S1

Whole process management

Warehouse business requirements for the whole process of purchasing-inbound-production-outbound-picking-review packaging-collection-delivery

S2

Support both stereo library and flat library

Support highly automated (vertical warehouse/line side warehouse, etc.) or purely manual operation (flat warehouse/line side warehouse/ground stack/shelf warehouse) unified management of warehouses

S3

Comprehensively improve efficiency

The path management and dynamic planning of automation equipment can effectively improve the delivery efficiency of warehouse logistics

S4

Effectively improve space utilization

The AS/RS, compared with traditional warehouses, improves space utilization by 4-7 times

S5

Intelligent system integration

It can integrate third-party automation equipment, such as robots, AGV, etc.

S6

Optimize information management

The accounts are consistent, the whole process can be traced, and the reconciliation is simple and efficient

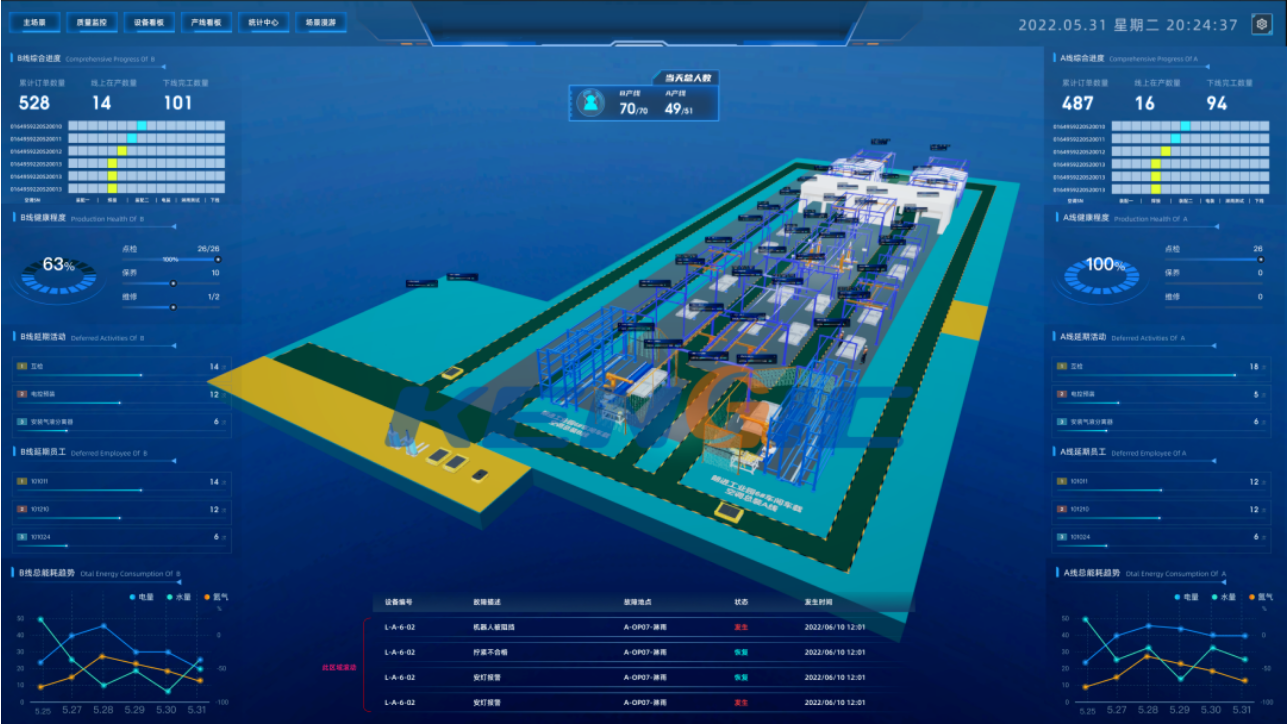

The end-to-end solution can rely on powerful data management and big data computing capabilities to centralize different data and systems on the platform for unified management, and the modular function configuration is extremely flexible and efficient.

①It can be connected to different business systems, such as SAP, MES, SRM, etc.;

②It can be connected to different sensing devices, such as RFID electronic tags, cameras, GPS, sensors, etc.;

③It can be connected to different hardware devices, such as stacker, pallet machine, gantry robot, etc.

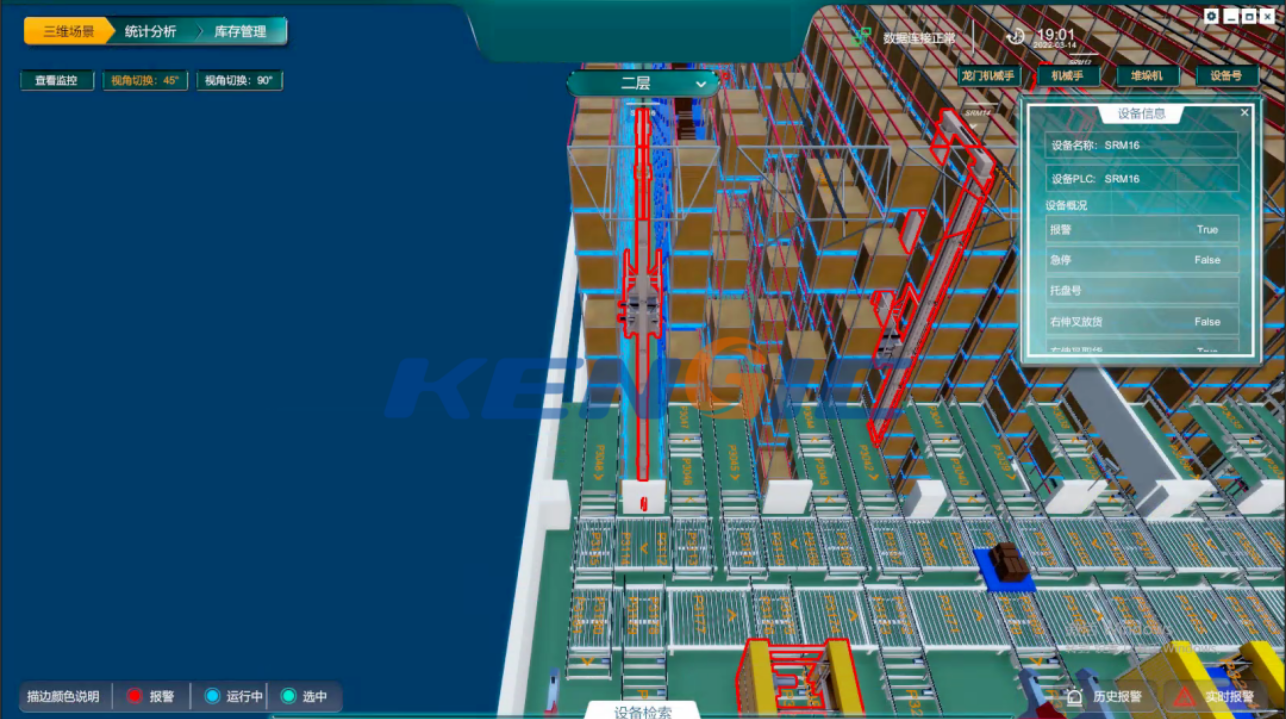

At the same time, it provides a 3D visualization system to break down the barriers between business systems and equipment to meet more customization needs.

WMS Solution Project

In the RRS large-scale logistics unmanned distribution center project, the WMS system provided by KENGIC covers the whole process of refined operations in the warehouse and in and out of the warehouse. Combined with WCS and TMS and system authority configuration, it realizes 10,000m² dismantling, picking and delivery The intelligent and efficient operation of warehousing, transportation, and distribution in the cargo area facilitates the intelligent and unmanned transformation and upgrading of large-scale logistics.

Centralized location management for timely information feedback and control

Realize high-efficiency paperless automatic operation and improve the efficiency of warehouse entry and exit

Contactless inventory management, suitable for special environments such as black lights and low temperatures

Avoid manual operation errors, reduce cargo loss and long-term operating costs

In the process of moving from manual warehouse to intelligent warehouse, build a comprehensive and reliable warehouse collaborative management platform to realize the digitization of operation information, transparent operation process, precise warehouse management and multi-platform integration.

As a system solution integrator for the two-wheel drive of intelligent logistics and intelligent manufacturing business, KENGIC conducts customized development based on the overall system planning, and can integrate the WMS system with the lean management needs of manufacturing customers to better empower multiple industries Enterprise supply chain management.

About KENGIC

KENGIC Intelligent Technology Co., Ltd. is a provider of intelligent logistics and intelligent manufacturing solutions with its own core technologies and products. The business scope covers enterprise digital consulting, project planning, professional system integration, equipment R&D and manufacturing, software R&D implementation, on-site installation and commissioning, and continuous after-sales service.

Guided by digital consulting and lean management as a means, the company provides customized intelligent conveying and intelligent sorting systems in the field of intelligent logistics, intelligent storage and intelligent factory systems and supporting facilities in the field of intelligent manufacturing through the overall business blueprint and structure planning of customers. Help customers realize the automation and intelligent upgrade of the trinity from logistics, warehousing to the overall factory.

Now it has delivered 500+ large-scale integrated project in express logistics, e-commerce new retail, home appliances, home furnishing, medicine and health, cold chain, auto parts, tires, new energy, new materials, chemical industry, communication electronics, equipment manufacturing, national defense and military industry, etc.

We will reply you within 24 hours