The apparel industry, from the perspective of the supply chain, includes upstream raw material production and processing, printing and dyeing processes, midstream clothing design and production, and downstream clothing sales; from the perspective of product types, it includes sports, formal wear, fast fashion and other categories.

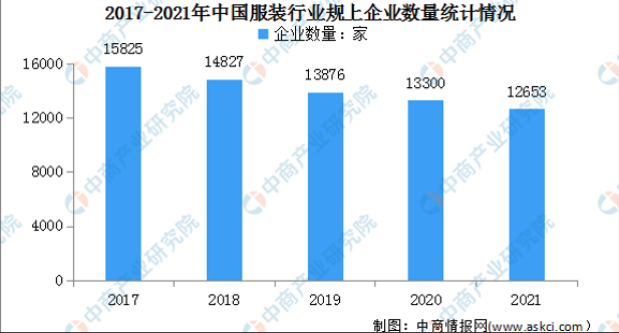

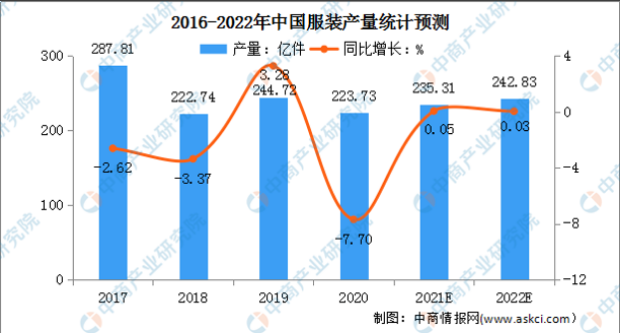

Driven by positive factors such as the current recovery of domestic and foreign market demand, the return of overseas orders, and relevant policy support, the production increment and output of the apparel industry have basically returned to the pre-epidemic scale. With the demand for industry upgrading and transformation, competition has become more intense, and the number of enterprises above designated size has declined.

Entering the new retail era, under the industrial trend of personalized consumer demand, diversified consumer channels, and fragmented consumer orders, the transformation of the supply chain of the apparel industry has begun.

The logistics characteristics of the distribution center of the footwear industry

Omnichannel delivery

Compatible with a variety of business models, while meeting the needs of future business expansion

Small batch, multi-category

Adapt to various consumer needs such as seasonal changes, clothing occasions, consumer groups, consumer preferences, etc., accompanied by differences in packaging and storage forms

Urgent time limit

Shorten the working time in the warehouse, increase the effective sales window, control and optimize labor costs, and pull through the synchronization of front-end and back-end data

Obvious periodicity

The actual business flow of arrival concentration, seasonal first shop, wave band distribution, and seasonal alternate warehouse withdrawal can reach as much as 10 times the daily amount, and the order volume during the big promotion period can reach 50-100 times the daily amount

Based on these logistics characteristics, creating a representative achievement of warehouse distribution integration in the apparel industry - an intelligent distribution center, faces the following pain points:

Pain Points of DC in the Apparel Industry

Multiple SKUs, multiple orders

Order flow fluctuates greatly

Diversification of omni-channel sales types (differences in order structure)

High return rate (2B peaks and troughs and 2C fast launch)

Service Advantages of System Solution Integrators

As a system solution provider, how KENGIC to clarify the pain point and difficulty of warehousing and logistics in the apparel industry, and give the idea of intelligent warehouse DC, and help enterprises create faster market response and more efficient upstream and downstream collaborative, more flexible warehousing and logistics, and then break through production limitations, better meet consumer demand, and cope with future business development?

The business of the apparel industry can be divided into five major modules: distribution, replenishment, B2C e-commerce, quick reactionand return.

For the intelligent distribution center, in the whole process of unloading and inbound, pallet/box storage, goods-to-person/person-to-delivery picking, sorting, review packaging, box/soft package delivery, etc., KENGIC has matching self-owned core automated logistics equipment to replace or help manual work to improve operating efficiency. At the same time, through mature large-scale project implementation capabilities, integrated AGV, robotic arm, unpacking disc system, etc., to provide customers with one-stop Landing plan and continuous after-sales service.

Reference Case of KENGIC Intelligent Apparel DC

KENGIC planned and implemented a new internal intelligent logistics system for a well-known designer brand in the apparel industry, combining the traditional DPS system and tote conveying system , steerable wheel sorting line, and cross-belt sorting technology to meet its B2B/B2C/OTO business needs and provide a strong support for its multi-channel logistics construction. This scheme is also a typical and representative building warehouse solution in the industry.

Eliminate delivery woes caused by labor shortages

Meet the brand multi-channel growth performance response efficiency

Realize the leap in timeliness and consumption experience in the new retail era

After communicating with a large number of service providers, I finally chose KENGIC. What I like is that KENGIC starts from a neutral point of view, understands our business process in depth, and defines individual needs. With an excellent team and high-quality resources, use Its own professionalism achieves the ultimate in program planning, process design, equipment production and installation, information configuration and commissioning, and also regards after-sales service as an independent link, giving us a one-stop perfect experience."

——Customer evaluation

Accurately understanding the needs of consumers and quickly satisfying them is the biggest goal of the growth and development of the apparel industry.

Solving the actual pain points of the customer's enterprise logistics supply chain is the direction and confidence of KENGIC continuous exploration and accumulation.

ABOUT KENGIC

KENGIC Intelligent Technology Co., Ltd. is a provider of intelligent logistics and intelligent manufacturing solutions with its own core technologies and products. The business scope covers enterprise digital consulting, project planning, professional system integration, equipment R&D and manufacturing, software R&D implementation, on-site installation and commissioning, and continuous after-sales service.

Now it has delivered 500+ large-scale integrated project in express logistics, e-commerce new retail, home appliances, home furnishing, medicine and health, cold chain, auto parts, tires, new energy, new materials, chemical industry, communication electronics, equipment manufacturing, national defense and military industry, etc.

We will reply you within 24 hours