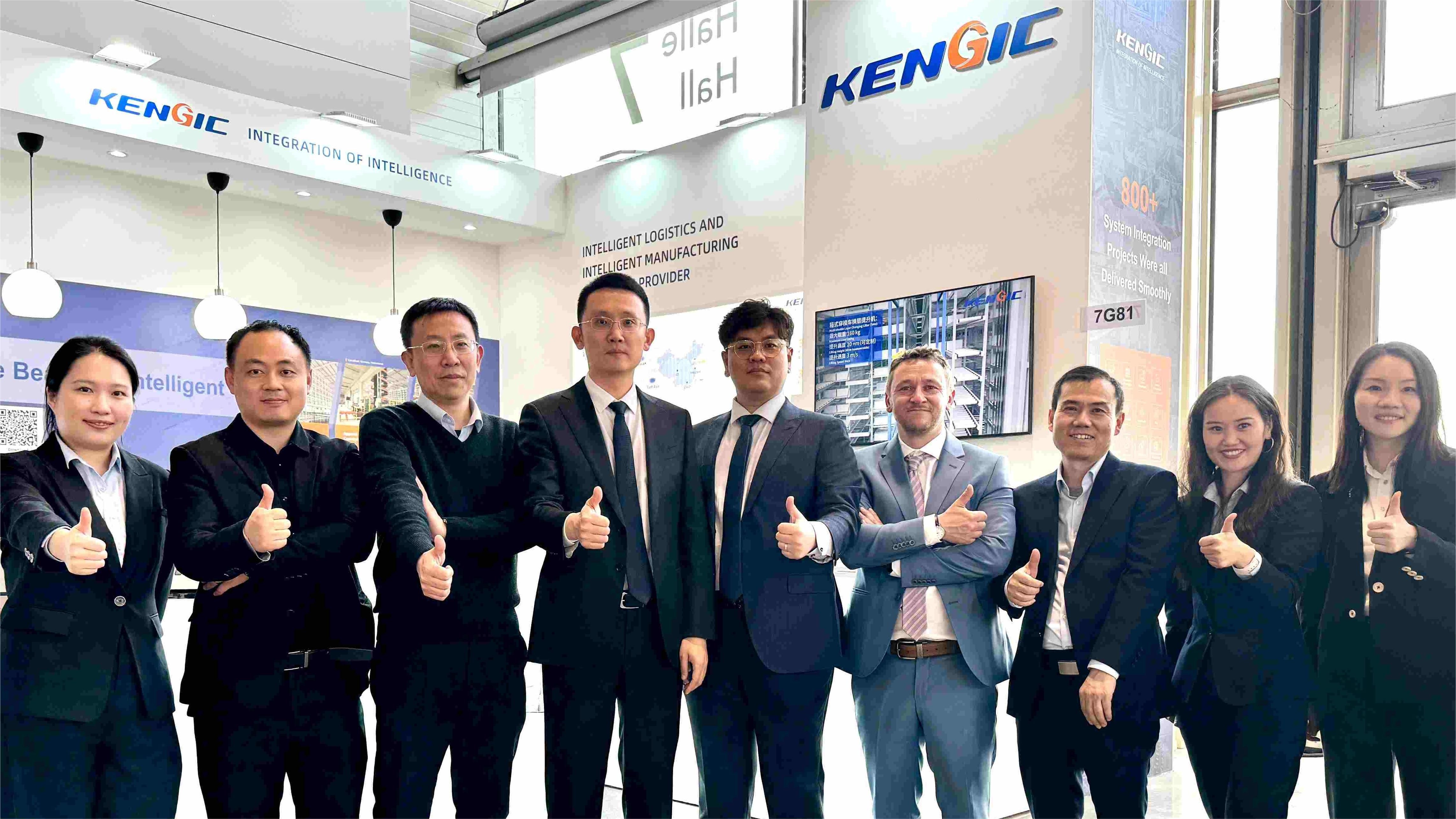

LogiMAT 2024, an international logistics exhibition known as the trend vane of the global logistics industry, ended successfully in Stuttgart, Germany with outstanding results. The exhibition was themed "Shaping Change Together, Sustainability, Artificial Intelligence, and Ergonomics". 1,580 world-class companies from 39 countries and regions showcased a variety of solutions and the latest innovative developments and technological products.

At this German Logistics Exhibition, KENGIC brought its integrated smart warehousing and distribution solutions to the exhibition, including smart sorting solutions for domestic and foreign express e-commerce industries, smart warehousing and distribution solutions for the food cold chain industry, smart warehousing solutions for the apparel industry, four-way shuttle systems for tote, and four-way shuttle systems for pallets. It demonstrated KENGIC deep strength and outstanding innovation capabilities to global customers, and expressed its beautiful vision of open sharing, cooperation and win-win.

At the exhibition, KENGIC warehousing and distribution center solutions quickly caught everyone's attention, and products such as the tote shuttle and pallet shuttle were also very attractive. Experts, representatives from many countries and regions, as well as media reporters and the public stopped at KENGIC booth to visit and check in, and actively interacted with our staff. The lively atmosphere and frequent communication demonstrated the strong development momentum of my country's intelligent warehousing and distribution solutions in overseas markets.

Exhibits on Display

Exibits on Display

Tote Multi-shuttle System

Pallet Multi-shuttle System

The three-in-one high-speed lift independently developed by KENGIC is a high-speed lift that integrates outbound storage, inbound storage, and layer change. When it is used as an outbound/inbound lift, its main function is to complete the outbound and inbound tasks of turnover boxes and fiber widths; when it is used as a layer change elevator, its main function is to assist the trolleys to change layers at different levels in the same lane according to order requirements, while also taking into account the maintenance of the trolleys on and off the shelves. When the multi-layer shuttle car and the high-speed elevator are used together, it can solve the problems of goods outbound and inbound storage, trolley layer change, and maintenance in a very cost-effective manner. In addition, it can be equipped with a mother car lane change system to solve the problem of trolley lane change.

Project Cases

Project Cases

Overseas apparel industry cross-belt project

【Project Introduction】 The project is mainly used for light conveying combined with a screw conveyor. Its area includes a tote conveying and sorting area, a picking area, and a goods collection and return area, with an efficiency of 2,000 packages/hour; the Dutch warehouse is mainly used for light conveying, with an efficiency of 1,500 packages/hour.

Overseas express e-commerce project

【Project Introduction】Large-scale express e-commerce sorting center in Southeast Asia, with a site area of over 60,000 square meters and a daily parcel processing volume of over 1 million pieces.

【Scope of Supply】18 sets of DWS matrix sorting, 1 set of ultra-small cross belt (260+ vehicles), 3 sets of double-layer small cross belt (3500+ small vehicles), and one set of parcel cross belt (870+ small vehicles). The total length of the project conveyor line exceeds 5000m.

【Solution Advantages】 Help customers solve the "fast, accurate, and stable" needs, improve sorting efficiency, improve sorting accuracy, optimize warehouse management costs, and improve data security and traceability.

At the second session of the 14th National People's Congress, hot words related to the logistics industry were frequently mentioned. KENGIC will keep pace with the national development strategy, focus on the low-altitude economy, lead the innovation and development of various industries with new quality productivity, and go global with customers from various industries; based on smart logistics, continue to promote the steady upgrading of warehouse and distribution intelligence, promote industrial innovation with technological innovation, and contribute KENGIC strength to actively promote industrial digitalization.

<END>

We will reply you within 24 hours

No. 132-1, 201, Gao Yi Road, Gaoyang City, Gyeonggi Province, Republic of Korea

QD HQ (North China): No. 21, Jinye Rd, High-tech Zone, Qingdao City, Shandong Province, China

SH Branch (East China): Building 23, Libo Business Center, Lane 379, Hongmei South Road, Minhang District, Shanghai City, China

CD Office (Southwest China): Room 2103, Taizhoushangren Building, Zhaojue Temple, No. 80 Heng Road, Chenghua District, Chengdu City, China

GZ Office (South China): Room 2112, Yanqiao Building, No. 89 Yanling Road, Tianhe District, Guangzhou City, Guangdong Province, China

SZ Office (South China): Room B1, 13th Floor, Building 12, Lehui Science and Technology Innovation Center, No. 489 Jihua Road, Bantian Sub-district, Longgang District, Shenzhen City, Guangdong Province, China

SZ Office: Room 2007, 20th Floor, Litong Building, No. 158 East Wuzhong Road, Wuzhong District, Suzhou City, Jiangsu Province, China

HF Office: Changjiang DoBe WE" International Hub, Luyang District, Hefei City, Anhui Province, China

Hotline: +86 021-61280216

E-mail: marketing@kengic.com

COPYRIGHT ©2018 KENGIC INTELLIGENT TECHNOLOGY CO.,LTD..All Rights Reserved. 鲁ICP备18025465号-1 Powered by:Hicheng

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.