Medical Devices

The data shows that from 2017 to 2021, the market size of China's medical device industry was increase from 443.5 billion yuan to 964 billion yuan, with a compound growth rate of 21.47%. It is expected to continue to maintain a good momentum of rapid growth and at the same time realize the process of import substitution from low-end products to high-end products. It is estimated that the scale of China's medical device market will exceed 2.2 trillion yuan in 2030.

References: National Bureau of Statistics, China Commercial Industry Research Institute

From upstream raw material and parts supply, midstream medical equipment, in vitro diagnostics, high/low value consumables processing and manufacturing to downstream scientific research institutions, medical and health institutions, third-party inspection institutions and individual patients, and the medical device industry has also formed a relatively mature industrial chain.

With the steady development of China economy and the continuous increase of policy support, facing the global market with strong demand, the medical device industry has entered a new cycle of high-quality development in China.

The high-quality players in the medical device industry are competing to conduct in-depth coordination and effective deployment in terms of supply chain optimization, technological innovation, market concentration improvement, international development, and digital and intelligent operations.

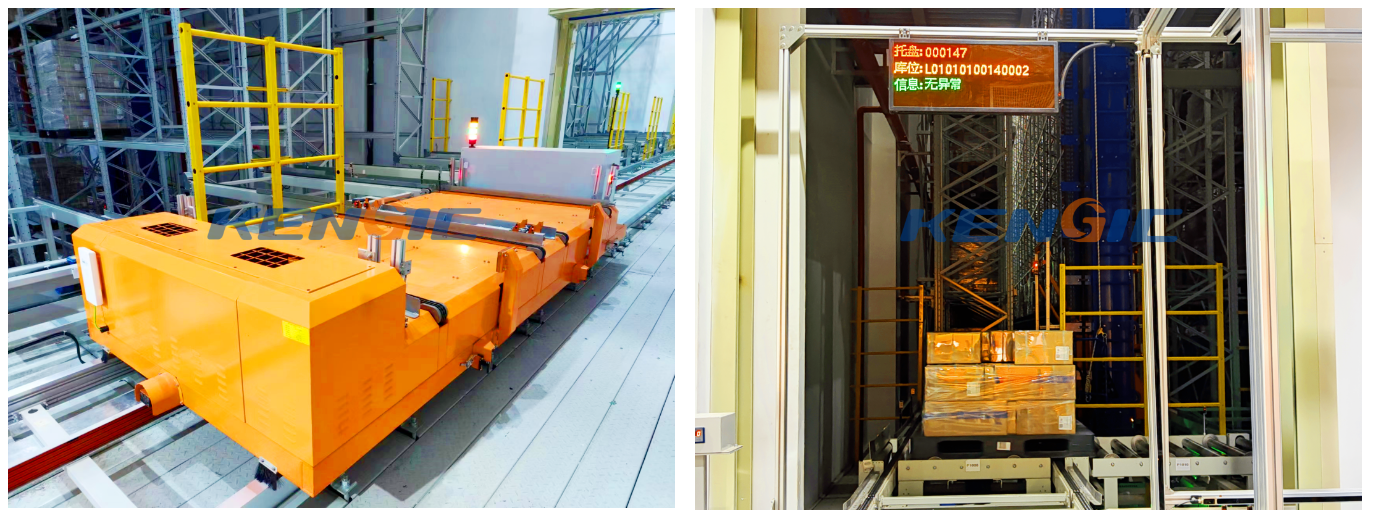

As a provider of efficient system solutions for intelligent logistics and intelligent manufacturing, KENGIC has delivered a number of projects in the fields of medical devices and pharmaceuticals, covering various scenarios such as production, handling, picking, sorting, receiving and shipping, etc.

With intelligent scheme planning and design technology, hardware equipment, core technology of electronic control and core technology of software system, it supports the one-stop full-process service and wins the favor of customers.

In 2020, KENGIC created a set of intelligent storage management solutions for a listed top 500 domestic company specializing in biomaterials and high-tech medical devices, which is used for the automated storage and storage of finished medical device products and related accessories and packaging materials. Warehouse management empowers the digital and intelligent construction of the group's supply chain. Two years later, let's walk into this operating system and see how it meets customer needs with real capabilities.

Functional Division

1

AS/RS, flat warehouse area, material receiving area, raw and auxiliary material conveying area, delivery area, palletizing and sorting area, sampling inspection area and control area

Scope of Supply

2

SRM system, pallet conveying system, double-station RGV shuttle system, shape and weight detection system, electrical control system, WMS/WCS software system

Environmental Requirements

3

AS/RS Temperature<30℃,

Relative Humidity<75%

Mode of Operation

4

All materials are automatically inbound and outbound of the warehouse through the WMS system, SRM system, and conveying system

2022 is a critical year for the "14th Five-Year Plan" and an important period for the golden development of the medical device supply chain.

As a strategic industry closely related to human life and health and high-tech compound intersection, digital intelligence empowers the medical device ecosystem, relying on the application of automated logistics equipment and the construction of an intelligent warehouse management system, and improving the level of warehouse management in an all-round way, reducing manual dependence, realizing accurate and efficient sorting operations, and saving unnecessary operating costs have become important reasons why KENGIC has been picked by many high-quality customers.

KENGIC is contributing to the development of "Intelligent" manufacturing in China medical device industry.

We will reply you within 24 hours