The article comes from LOGISTICS TECHNOLOGY AND APPLICATION magzine (Reporter/Jiang Hong)

At the 22nd Asia International Logistics Technology and Transportation System Exhibition (CeMAT ASIA 2021) to be held from October 26 to 29, 2021, KENGIC Intelligent Technology Co., Ltd. (referred to as "KENGIC Intelligent") made a wonderful appearance in Hall W2 , Focusing on displaying the company’s five major solutions and three innovative products in the form of multimedia interaction.

Mr. Xue Liyuan

Mr. Xue Liyuan

The vice general manager & general manager of intelligent logistics division

of KENGIC Intelligent Technology Co., Ltd.

Mr. Xue Liyuan, vice general manager and general manager of Intelligent Logistics Division of KENGIC Intelligent Technology Co., Ltd., was interviewed by us. He said: “Under the background of the normalization of the epidemic and the transformation and upgrading of manufacturing industry and high-quality development in China, the entire industry is still booming. The market is large enough and the market demand is sufficient. Based on this situation, The overall business of KENGIC Intelligent this year is also good. The performance of the company's four major business division has achieved relatively large growth."

Professional Solutions Provider

Founded in 2015, KENGIC Intelligent is a professional intelligent logistics and intelligent manufacturing solutions provider, as well as a professional integrator of its own core technologies and products. It mainly provides customers with consulting, planning, R&D and design, manufacturing, delivery and implementation, and after-sales guarantee services of intelligent logistics and intelligent manufacturing systems and products. The company is headquartered in Qingdao, with R&D and manufacturing bases, as well as branches in many places in China, serving customers all over the country.

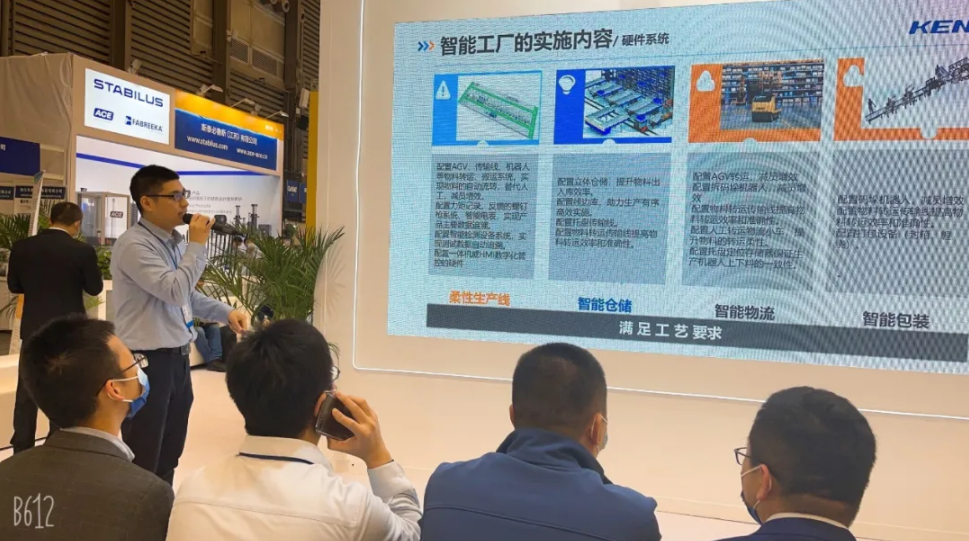

KENGIC Intelligent currently provides intelligent factory solutions, intelligent warehousing solutions, intelligent conveying solutions, intelligent sorting solutions and intelligent information solutions. The two interactive sand tables exhibited this year also fully demonstrated the interconnection of these five solutions. The strength of KENGIC Intelligence as a system integrator can be comprehensively demonstrated:

Smart factory solution sand table: It shows the storage, processing and production of raw materials, the optimization of material logistics, the construction of the internal information system of the factory, the storage, picking and distribution of finished goods that can be used in typical discrete industries. Help customers build digital smart factories in the raw material warehouse, semi-finished product warehouse warehousing, component machining, component assembly, laser cutting, sheet metal welding, assembly flexible assembly, in-plant logistics optimization, equipment interconnection, data collection and other links.

Smart factory solution sand table

Smart factory solution sand table

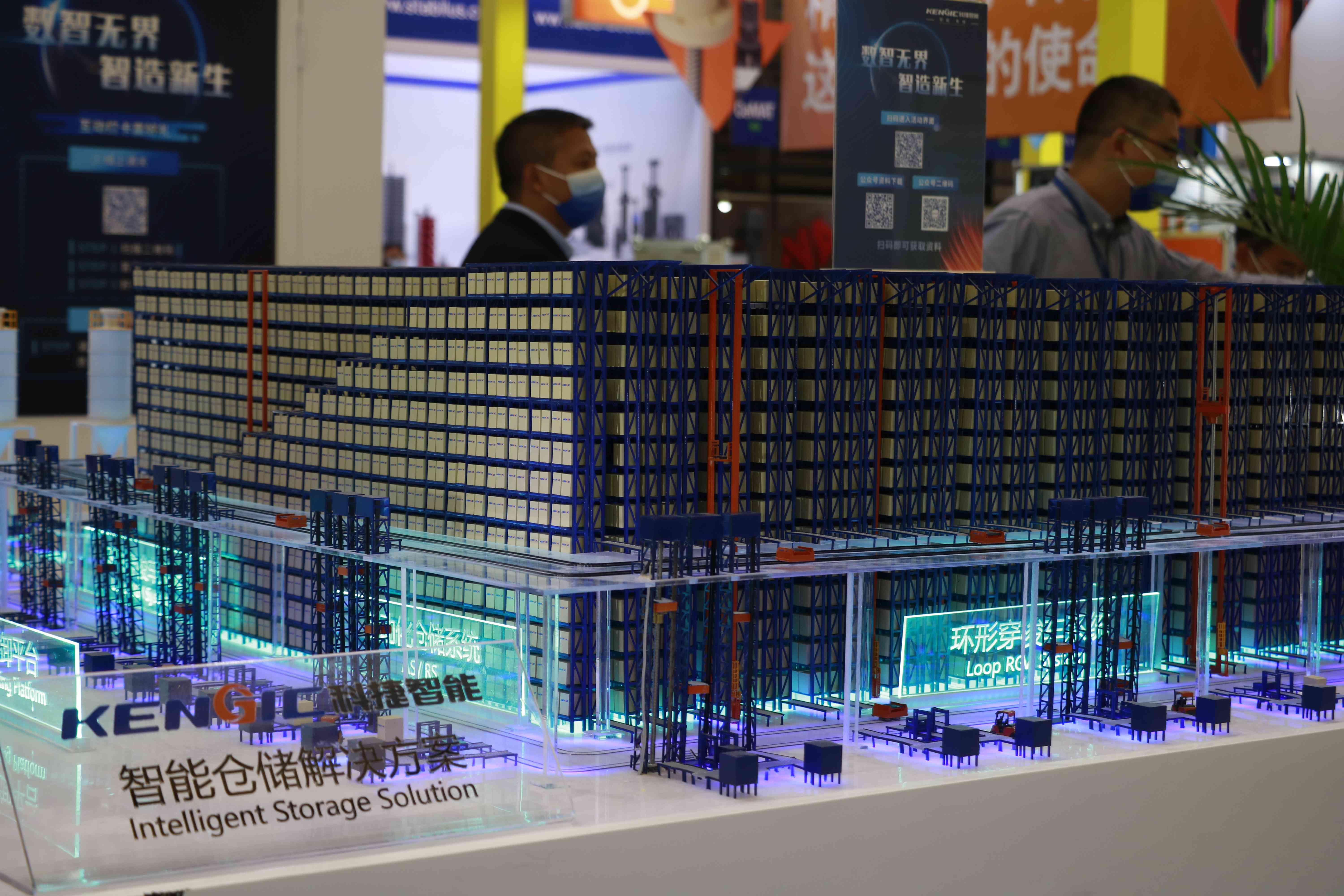

Interactive sand table of intelligent warehousing solutions: It displays a set of comprehensive solutions integrating sorting planning, conveying planning, warehousing planning, software information planning, etc., through the integration of automated AS/RS, circular shuttle systems, and intelligent conveying and sorting systems, intelligent material handling systems, automated packaging systems, automated palletizing systems, automated loading and unloading systems, robots, AGVs, warehouse control systems and supporting software systems, etc., showing a complete set of full-process intelligent solutions, customized to meet customer needs, help customers improve work efficiency, optimize work processes, and reduce labor intensity and labor costs.

Three new products are unveiled

KENGIC Intelligent is a system integrator with its own core technology and products. At the product level, it mainly provides customers with intelligent conveying systems and intelligent sorting systems in the field of intelligent logistics, as well as intelligent storage systems and intelligent factory systems in the field of smart manufacturing. And according to the customized requirements of the customer's solution, integrate other various advanced technologies and special equipment, and deliver the complete system to the customer in a one-stop turnkey project service mode.

In the interactive new product cabinet at the exhibition site, the three latest products displayed by KENGIC Intelligent attracted the attention of the audience.

1. High-speed stacker system

Compared with the conventional crane stacker, the main difference of KENGIC Intelligent high-speed stacker is reflected in the change of the running structure. The bearing box structure in the form of rubber-coated wheels is adopted, and both ends are controlled by servo motors, which are safe, stable and high cost performance. In terms of technical parameters, the traveling speed is 240m/min, the lifting speed is 90m/min, the fork speed is 90m/min, and the maximum load is 1.5t. It can be widely used in warehousing link of many industries, such as machinery, electronics, automobiles, tires, medicine, furniture, cold chains, chemicals, etc.

2. Four-way RGV system (Tote)

The four-way RGV system has the characteristics of high-density storage, highly flexible picking, good ductility and adaptability, rapid deployment, safety and reliability. In this system, the shuttle can travel in multiple directions without being restricted by space, and can realize cross-lane, cross-layer, efficient and flexible operation. The main technical parameters of the four-way shuttle car with bins: the maximum speed is 5m/s, the maximum load is 50kg, and the positioning accuracy is ±3mm. The characteristics of the system are: the core equipment adopts standardized and modular design, which can meet the needs of business expansion; the heuristic search algorithm can be used to achieve the most streamlined path planning; the use of high-order S-curve control technology and 5G communication technology can guarantee the equipment operational efficiency and safety.

3. Fully automatic shipment supply system

In the business scenario of express sorting, the centralized supply of small parcels has always been a difficult point: because they are thin and light, problems such as overlapping and missing scans are prone to occur. The latest automatic small parcel supply system of KENGIC Intelligent is mainly used in the front end of the automatic sorting system. It consists of a stack separation belt conveyor, a scattering belt conveyor, a single separation belt conveyor, a vision system, a stack detection belt conveyor and balance wheel. The parcel is separated by the stack separation belt conveyor, and the gap is opened by the scattering belt conveyor and then enters the single separation belt conveyor. At the same time, the real-time position of the parcel is captured by the vision system, and the optimal separation order and path are calculated through the algorithm. And then adjust the posture of the parcel by the single-piece separation belt conveyor to realize the separation, pulling distance and queuing of the package, and then pass the detection by the stacked detection belt conveyor, and finally remove it by the balance wheel.

The efficiency of KENGIC Intelligent automatic shipment supply system can reach 8000 pieces/hour, the single-part separation accuracy is as high as 99.9%, and the thinnest express delivery height can be as low as 1mm. At the same time, the vision system also has the ability of in-depth self-learning, which can optimize the algorithm in time according to the changes in conditions such as the shape of the parts in the business scene. It is understood that the system has been validated by the market and can replace labor and improve efficiency in the package supply link, and has been highly praised by many customers.

Technology R&D Direction

R&D has always been a key focus and investment link of KENGIC Intelligent. In Mr Xue’s view, whether it is intelligent logistics or intelligent manufacturing, it should be said that the industry has developed relatively mature solutions and key equipment after nearly 10 years of rapid development. Therefore, at this stage, it is difficult to say that there will be disruptive major innovations emerge. In this situation, KENGIC Intelligent has focused its R&D work in two main directions:

One direction is application-based technological transformation and upgrading, which is closely integrated with the customer's business scenarios. In the process of serving customers, KENGIC Intelligence often collects customer needs for system efficiency improvement, automation upgrades of certain manual links, etc., after evaluation and demonstration, R&D projects will be initiated, and targeted iteration or product development will be carried out and solve the pain points of customers.

The other direction is R&D and upgrading based on new technology, which is more reflected in the control and software level. For example, path control systems based on 5G communication technology, intelligent dispatch systems, 3D monitoring platforms, and smart factory MES systems under the background of big data and cloud computing technologies.

Future development expectations

Speaking of future industry development trends, Mr Xue believes that in the context of new infrastructure, economic internal circulation, technological independent innovation, and support for the development of the real economy represented by the manufacturing industry, whether it is intelligent logistics or intelligent manufacturing, it will continue to maintain a relatively rapid development trend, and the overall market demand will be relatively strong this year and for a long period of time in the future. This undoubtedly gave KENGIC the confidence in the development of intelligent.

"Since the company was founded, it has gained a certain degree of precipitation and accumulation in many aspects. At this stage, we have our own clear development goals, strategic planning and business layout, and we also have hopes for the future." said by Mr Xue. "In terms of short-term goals, we hope to grab the opportunity of rapid market development and achieve steady growth in business scale step by step. At the same time, in the process of project delivery, we will continue to upgrade technology and product polishing to improve organizational capabilities and operational efficiency to realize the digital transformation of enterprises and provide customers with better services. In terms of medium and long-term goals, we hope that through unremitting efforts, we can realize the company's own vision-to become the world's leading provider of smart logistics and intelligent manufacturing solutions, and at the same time , I also hope that in the development process of our country starting a new 100 years and becoming a world economic power, under the great changes unseen in a century, KENGIC Intelligent works with industry friends and colleagues to contribute to our country’s industrial transformation and upgrading and high-quality development."

It is reported that KENGIC Intelligent has been accepted for its IPO on the Science and Technology Innovation Board on June 30, 2021. It is believed that with the trust of the capital market, KENGIC Intelligent will accelerate toward the set goal.

We will reply you within 24 hours