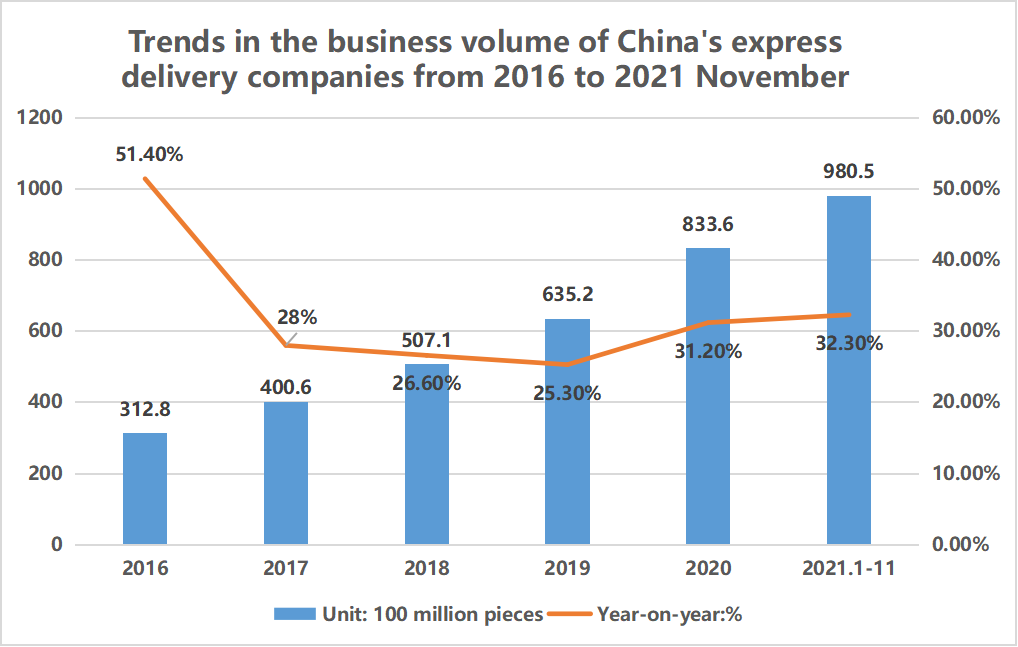

China has the world’s largest express delivery business volume and the most developed e-commerce market. After nearly 10 years of rapid development, the intelligent logistics equipment companies that emerged in the world have precipitated relatively mature solutions and key equipment to promote overall logistics. The industry has gradually moved from "scattered, chaotic, and poor" to "standardization, large-scale, and high-efficiency". In particular, automated sorting systems represented by cross-belt sorters and steerable wheel sorters are becoming more popular and optimized. At present, they have performed quite well in terms of operating speed and equipment performance, and the industry technology gap is gradually narrowing.

resource from: www.askci.com

resource from: www.askci.com

However, as the volume of parcels grows, the requirements for express mail turnover and venue efficiency are getting higher. How can we further improve the operational efficiency and service quality of major distribution centers on the existing basis? Guided by the actual needs of top customers, we focused on making breakthroughs in the express delivery package.

At present, the front-end package supply mode of the domestic automated sorting system is divided into manual shipment, semi-automatic shipment and fully automatic shipment. The package supply station is divided into package loading section, acceleration section and lead-in section. Due to the difference in artificial physical strength and ability, it is also affected by the availability of online carrier. In actual operation, the efficiency is more difficult to control, which will also affect the overall level of the back-end automated sorting system. Therefore, KENGIC has devoted itself to the research and development of a set of fully automatic shipment supplying system solutions, which can greatly improve the efficiency and accuracy of shipment, and realize the whole process unmanned operation from manual unpacking to the intermediate link of cross belt or steerable wheel sorting.

KENGIC fully automatic shipment supplying system is applied to the front end of the automated sorting system, which is mainly composed of three parts: small parcel singulation system, high-speed small parcel conveying system and high-speed small parcel automatic supplying system, which supports seamless connection of various types of automation sorting equipment. At present, two series of products are designed and developed, unidirectional supply steerable wheel sorting, with an efficiency of up to 8,000 pieces per hour, and bidirectional supply cross-belt sorting, with an efficiency target of up to 10,000 pieces per hour. Compared with the traditional manual and semi-automatic mode, it has the characteristics of modular design, compact structure, strong sorting ability, wide application range and high investment cost performance, and the system availability reaches 99.99%.

The system is at the leading level in the industry in China. At present, only one foreign competiter can handle 10,000 pieces per hour, while only three or four domestic companies are doing related research and development, especially the problem of missing parts in ultra-thin envelopes.

The system has taken the lead in practical applications in Shanghai, Hangzhou, Huizhou and other project sites. It has a good performance in terms of efficiency and performance. By the end of the year, it can complete the prototype development of 10,000 pieces of equipment per hour. It is expected to enter the test application next year. .

|

|

| Ladder de-stacking system The ladder separation design separates the piles of parcel in layers, which can effectively eliminate the crowded stacks problem of soft packages and improve the success rate and efficiency of separation. |

| Singualation system The parcel is stretched, separated, rotated and straightened, and unidirectional or bidirectional is set according to the back-end requirements. |

| Stacking and special-shaped parcel detection system High-precision package recognition through 3D camera, in-depth detection of oversized parts, special-shaped parts, under-drawn parts and channel flow, and enhance the trigger signal of the steerable wheel. |

| High-speed small parcel steerable wheel sorting system Intensive sorting modules and subdivided sorting units can realize 120*120*1mm ultra-small parcel rejection, single-flow linear sorter feed-in and flow distribution. |

| Shunt draw distance system Match the flow of the induction station to divide the parcel and draw the distance, and mechanical selection and straightening function for secondary posture adjustment of parcel to improve the accuracy rate of goods entering the carrier. |

| High sorting efficiency The unidirectional efficiency can reach up to 8000 pieces per hour, and the singualtion accuracy rate is as high as 99.9%. |

| | Strong sorting ability The maximum weight of the sorted parcel is 8kg, and the height of the thinnest sorted parcel can be as low as 1mm. |

| Compact structure High adaptability, the minimum height of the device itself is 500mm, and the maximum height can be adjusted. |

| Modular structure Modular design, stable equipment, convenient installation and maintenance. |

| Cost-effective High return on investment, reducing labor and increasing efficiency. |

| Wide range of applications The minimum size of the sorted parcel is 120mm*120mm, and the maximum is 465mm*380mm; it can be applied to various packaging forms, such as cartons, envelopes, and waterproof bags. |

Catalyzed by the epidemic, the entire market has more stringent tests on personnel, efficiency, and speed, and labor shortages and labor costs will become more prominent in the future. On the road of accelerating enterprises to reduce costs and increase efficiency and improve service quality, intelligent logistics system solution integrators play an extremely important role in logistics hardware, logistics software, overall planning, system integration, and platform resource integration.

KENGIC has a very competitive core product advantage, a rich series that adapts to different scenarios, while performance and quality are in line with international standards, the market has a strong response speed and ability to iteratively update. It can quickly insight into customer needs and provide them with customized solutions and innovative products.

Whether in the express delivery or e-commerce industry, KENGIC has rich project experience and leading partners. We always adhere to customer demand-oriented, based on the actual needs of customers at different stages, improve the performance of existing products, actively innovate and develop, and use intelligent layout to help customers achieve maximum value.

We will reply you within 24 hours