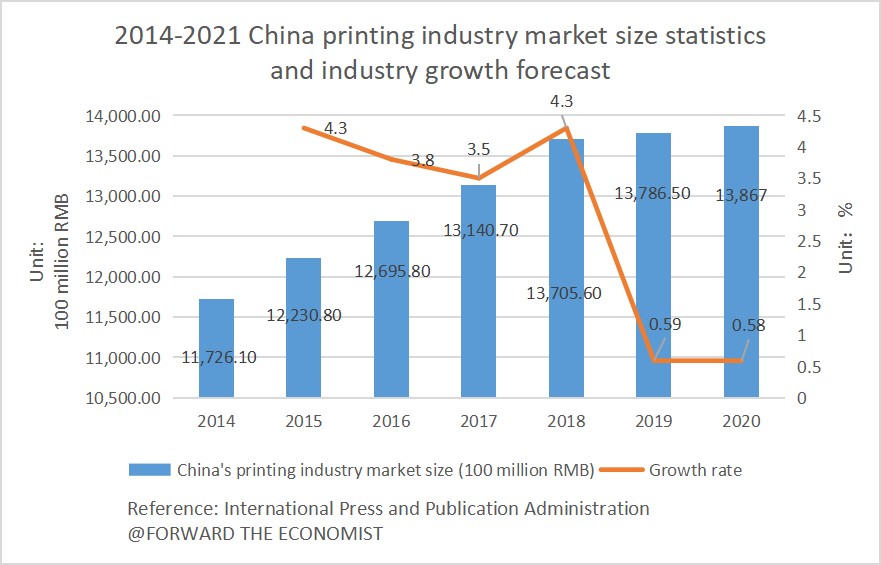

Printing and packaging products are widely used in food and beverage, express delivery, medicine, daily chemical, press and publishing industries. With the development of society, there is high demand of market, and the overall scale is growing steadily.

In recent years, although it has been affected by various objective environments such as electronic media, the pandemic, and the economic downturn, it has also been accompanied by the relevant policy support in the "14th Five-Year Plan" and the 2035 goal of "improving the level of social public services, prospering the press and publishing industry, and advocating green packaging". At the same time, the printing industry is also actively promoting innovation and transformation, industry integration, intelligent layout and other measures, trying to break through the industry's current SKU diversification, order customization, fast turnover and low inventory, and complicated and error-prone warehousing work. to achieve corporate differentiation and sustainable development.

As a leading enterprise in the printing, packaging and publishing industry in northern my country, Tianjin Haishun Printing Co., Ltd. is a large-scale modern comprehensive printing and packaging enterprise integrating design and plate making, color printing, post-press processing, and warehousing logistics. Haishun Printing is a national printing demonstration enterprise. It has won the China Publishing Government Award Printing and Copying Award issued by the State Administration of Press, Publication, Radio, Film and Television. In 2018, it was rated as one of the “Top 100 Printing and Packaging Enterprises in China”.

In 2020, Tianjin Haishun Printing Industry Package Co., Ltd. has chosen a comprehensive system solution integrator, KENGIC Intelligent, to build its first automated three-dimensional storage system, open up data connections in various regions, realize equipment interconnection, further save labor costs, improve production flow efficiency, and help Haishun build production automation Intelligent manufacturing deployment integrating control, scheduling, automatic optimization and resource planning management.

The project landed in Tianjin and designed 2872 locations. The scope of supply covers SRM system, pallet conveying system, lifter system, electrical control system and information software system.

Mached pallet tomeet the customization

During the warehousing operation, the pallet cargo is wrapped with film and scanned, and the sub-pallet with the cargo is placed on the mached pallet of the rotating table by a custom-sized fork lifter.

The front end of the fork lifter is equipped with a visual recognition system. After the pallet are combined, they can confirm whether the mached pallet needs to be rotated by scanning the code and feedback. If the pallet transported by the cattle is confirmed to be a mached pallet, it does not need to be supplied separately. The fork lifter directly forks the mached pallet and puts it on the rotating table.

The rotating table is equipped with shape detection and clamping auxiliary devices to automatically regulate the over-side cargo, and then enter the conveyor line in front of the warehouse.

Respond to traffic changes in a flexible and efficient way

According to the actual business needs of customers, the storage efficiency of a single stacker can reach 39 pallets/hour, and the delivery efficiency can reach 42 pallets/hour; the efficiency of a single fork lifter can reach 34 pallets/hour.

In a certain period of time, there may be unequal flows of in and out of the warehouse. For this, KENGIC Intelligent has planned the corresponding equipment control mode flexibly, and designed buttons at the entrance and exit:

Manually toggle the button when it needs to be inbound, and the conveying equipment is in the inbound mode;

Manually toggle the button when it needs to be outbound, and the conveying equipment is in the outbound mode;

When there are both outbound and inbound, the third mode can be selected, and the conveying equipment is in two-way conveying mode.

Information exchange and visual management

Long supply chains, weak information system construction, and high coordination costs are important reasons that hinder the development of the industry.

The AS/RS WAS system provided by KENGIC Intelligent comprehensively covers SKU management, safety management, system parameter, order management, carrying unit management, cargo location management, inventory management, wave management, transportation management, picking management, sorting management, and cargo location visualization, equipment status visualization, report analysis and other modules, open up real-time data tracking and equipment interconnection for demand, inventory and logistics, and establish a set of agile and flexible decision-making response system.

In view of the characteristics of printed packaging products, the system can realize the real-time check of the status of inventory cargo in a colorized and visual manner, and can quickly check damage problem, improve management efficiency, reduce inventory loss, and ensure the quality of delivery.

The implementation of this project is an important part of Haishun Printing's strategic layout with information data as the core main line, automated printing equipment + automated AS/RS system + intelligent logistics equipment + robot application, and assisting it through refined management and lean Production, to create a digital, automated, intelligent, and green smart printing factory.

For printing and packaging companies, intelligent construction is a trend of development in the era of Industry 4.0, responding to the advancement of national policies and standards, responding to rising operating costs, and continuous high-pressure market competition.

Intelligent warehousing, as an important part of it, can maximize the production efficiency of enterprises, optimize business processes, reduce manual dependence, reduce resource consumption, build a digital supply chain, and liberate the company's focus to the field of key technology research and development and innovation, and ultimately win a larger market.

We will reply you within 24 hours